Aerospace

Drones PCB Assembly Manufacturer

In the drone industry, PCBs are an essential component that ensures reliable operation across a wide range of devices. From recreational drones to advanced industrial UAVs, drones PCB technology is central to enabling functions like navigation, communication, and power management. As drones become more integrated into industries like agriculture, logistics, and surveillance, the demand for high-quality drones PCB assembly has grown significantly. This surge is driven by the need for compact, durable, and efficient electronic systems that can handle complex tasks and environmental challenges.

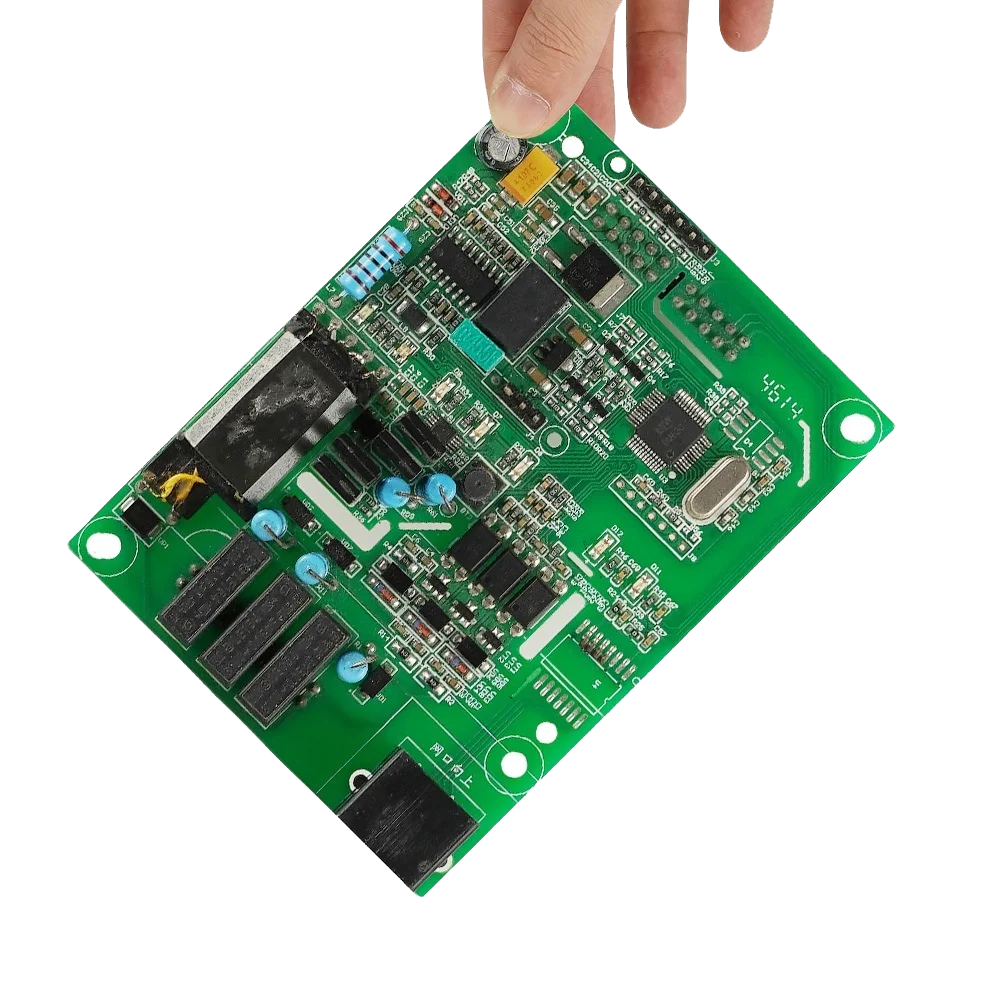

Lingkey’s Drones PCB Products

Lingkey has produced a variety of PCBs for the drone industry, supporting diverse applications. Our offerings include navigation control PCBs, power distribution boards, and communication modules tailored to UAV requirements. For instance, our high-frequency PCBs are ideal for drones requiring precise control, while multi-layer boards handle complex electrical systems in industrial drones. Each product is designed to maximize performance while maintaining lightweight and compact structures, critical for drone efficiency.

Delivery Process for Drones PCB Assembly

Lingkey’s delivery process ensures a seamless experience for clients, from design to deployment:

Requirement Analysis

We start by understanding the specific needs of the drone application, focusing on factors such as size, weight, and functionality.

Quality Assurance

Comprehensive inspections, including thermal and electrical testing, are conducted to ensure each PCB meets stringent standards.

On-Time Delivery

The PCBs are securely packaged and shipped promptly, arriving in perfect condition and ready for integration into drone systems.

Prototyping and Testing

Our team develops prototypes to verify performance and address potential issues before full-scale production. Each prototype undergoes rigorous testing to ensure reliability in demanding environments.

Full Production

Once approved, we initiate production using advanced techniques to create high-quality PCBs at scale.

Why Choose Lingkey for Drones PCB Assembly

Lingkey has established itself as a trusted supplier for the drone industry, offering unparalleled expertise in drones PCB assembly. Our certifications meet international standards, ensuring compliance with industry-specific requirements for reliability and safety. Every drone PCB we deliver undergoes rigorous quality checks to meet the high-performance demands of applications such as precision mapping, package delivery, and high-altitude photography.

Our efficient delivery process guarantees quick turnaround times, allowing businesses to keep up with market demands. Lingkey’s team works closely with clients to customize PCBs to their exact specifications, ensuring compatibility with advanced drone designs. This combination of technical expertise and commitment to quality sets Lingkey apart in the competitive drones PCB manufacturing market.

Drone PCBs face unique challenges in design and manufacturing, which mainly include:

Lightweight design

Drones are susceptible to weight.PCBs must be lightweight to reduce weight and improve flight efficiency and durability.

Environmental resistance

Drones often operate in external environments, including extreme temperatures, humidity, and vibration conditions.Therefore, PCBs need to have excellent environmental adaptability and durability.

High-density layout

Drones have limited space, requiring PCBs to accommodate more and more electronic components in a limited space.

Electromagnetic compatibility (EMC)

Drone PCBs need to have a good electromagnetic compatibility design to prevent signal interference and ensure the stability of flight control and communication systems.

To meet the above needs

Drone PCB manufacturers have adopted a variety of advanced technologies:

Innovation in the Drones PCB Industry

Lingkey’s expertise in drones PCB assembly empowers companies to innovate and push the boundaries of drone technology. By delivering reliable, high-performance PCBs, we help businesses meet the evolving demands of industries like agriculture, logistics, and defense. Please feel free to contact us at Lingkey anytime for all drone PCB needs.