Industrial

Lingkey: Your Trusted Partner in Industrial PCB Manufacturing

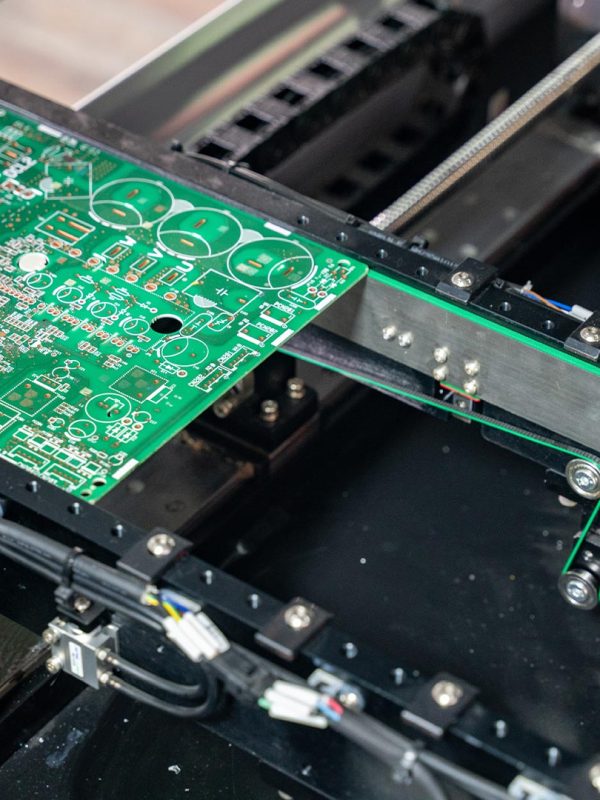

In the industrial sector, PCBs serve as the foundation for various equipment and systems, including automation controllers, power management solutions, and heavy machinery. With the increasing adoption of automation, IoT integration, and advanced manufacturing technologies, the demand for specialized industrial PCBs has surged. These circuit boards are engineered to endure extreme conditions—such as high temperatures, mechanical stress, and exposure to dust and moisture—making durability and precision critical to their performance.

High-temperature resistance

Our PCBs use special materials and advanced manufacturing processes to withstand continuous high-temperature environments and maintain circuit integrity and functionality.

Corrosion resistance

Using advanced anti-corrosion materials and surface treatment technology effectively resists chemical erosion and extends product life.

High mechanical strength

The reinforced structure designed for mechanical stress, vibration, and impact ensures that performance can be maintained under the most demanding physical conditions.

Optimized electrical stability

Through precise circuit design and strict quality control, it provides high electrical performance and stability and reduces failure rate.

Delivery Process for Industrial PCB Manufacturing

Lingkey’s streamlined delivery process ensures efficiency and reliability for every project:

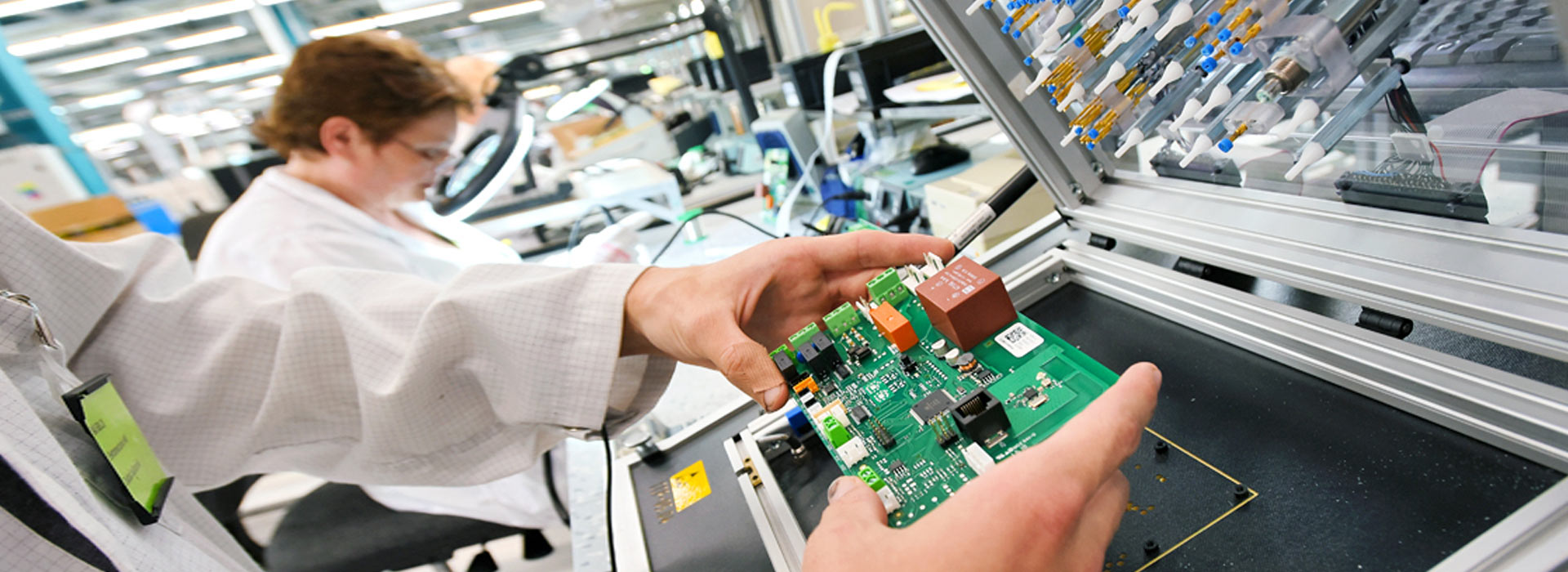

Our team conducts a thorough assessment of your specific equipment or system needs, focusing on dimensions, functionality, and durability.

We develop prototypes and perform exhaustive testing to validate performance and safety, identifying and resolving potential issues earlybefore full-scale production.

After prototype approval, we proceed with mass production using state-of-the-art equipment to ensure precision and uniformity.

Every PCB undergoes rigorous inspections, including electrical and environmental testing, to meet industrial-grade standards.

Products are securely packaged and shipped on schedule to align with your project timelines.

Why Choose Lingkey for Industrial PCB Manufacturing

Lingkey distinguishes itself as a dependable partner in industrial PCB manufacturing through its unwavering commitment to quality, efficiency, and customer satisfaction. Certified to meet stringent industry standards, we ensure every PCB is built to excel in demanding industrial environments. Our manufacturing processes prioritize precision and reliability, delivering consistently high-quality results with every production run.

Our delivery process is streamlined to meet tight deadlines, ensuring that clients receive their products on time. Lingkey’s quality assurance measures include rigorous testing at every stage, from material selection to final assembly, guaranteeing that our industrial PCB solutions perform reliably under the most challenging conditions. This dedication to quality and efficiency has made us a trusted name in the industry.

Lingkey’s Industrial PCB Products

Lingkey has developed a range of industrial PCB solutions to meet the growing needs of this sector. Our products include power distribution PCBs for heavy machinery, control system boards for automation equipment, and high-frequency PCBs for industrial communication systems. Each product is carefully engineered to withstand harsh environments and maintain performance over long operational cycles.

For example, our power management PCBs ensure stable and efficient energy distribution, critical for heavy-duty applications. Similarly, our control system boards are designed to handle complex operations in industrial automation, supporting precision and consistency in manufacturing processes. These solutions showcase Lingkey’s expertise in creating robust and high-quality PCBs for the industrial sector.

We remain committed to providing the best PCBs for industrial applications.

Lingkey’s expertise in industrial PCB manufacturing allows us to meet growing demands of modern industries. Our focus on quality, reliability, and customization ensures that every PCB we produce supports critical applications effectively.