Medical PCB Assembly and Manufacturing

Medical PCB Solutions for Medical Applications

In the healthcare industry, PCBs are a crucial component that ensure the reliable operation of various medical devices. From diagnostic tools to treatment equipment, medical PCB plays a key role in delivering accurate, consistent, and life-saving performance. The increasing demand for advanced, compact devices has driven the need for high-quality medical PCB manufacturing, as these components form the foundation for breakthroughs in patient care, monitoring, and surgical precision.

Delivery Process for Medical PCB Manufacturing

Lingkey’s delivery process is meticulously designed to provide seamless and reliable service:

Requirement Analysis

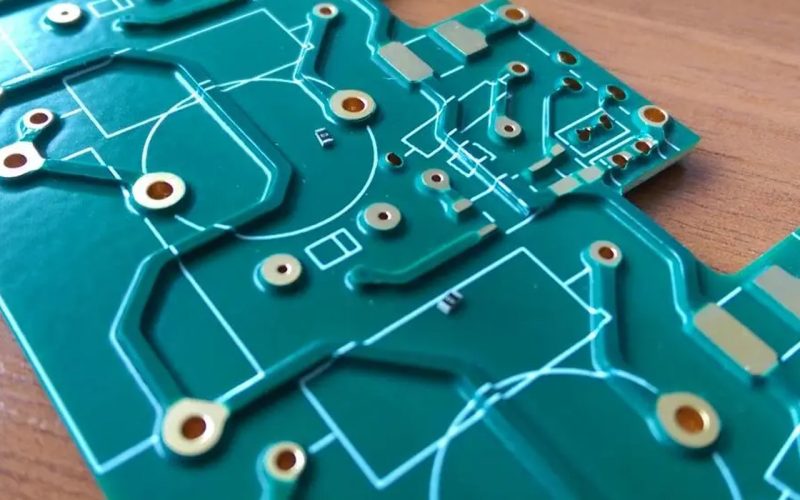

Prototyping and Testing

Before full-scale production, we develop prototypes to validate designs and ensure all functional criteria are met. Rigorous testing ensures the prototypes comply with industry standards.

Full-Scale Manufacturing

Upon approval, we commence manufacturing using state-of-the-art machinery and highly skilled technicians to guarantee precision and consistency.

Quality Assurance and Inspection

Each PCB undergoes comprehensive inspections, including electrical testing and thermal analysis, to verify reliability and durability.

On-Time Delivery

Once quality checks are finalized, we securely package and promptly ship the products, ensuring timely delivery in perfect condition.

Lingkey Medical PCB Manufacturing

Lingkey distinguishes itself as a trusted partner in medical PCB manufacturing through its unwavering commitment to excellence at every stage of the process. Our certifications adhere to the highest industry standards, ensuring full compliance with healthcare regulations and the safety of every product. We implement rigorous quality assurance protocols, ensuring each PCB meets strict tolerances and performs flawlessly in demanding medical environments.

Our streamlined delivery process allows us to meet tight deadlines while maintaining consistent product quality. Lingkey’s extensive experience enables us to handle both small and large-scale production requirements with ease. This combination of efficiency, reliability, and attention to detail has made Lingkey a trusted name in medical PCB solutions.

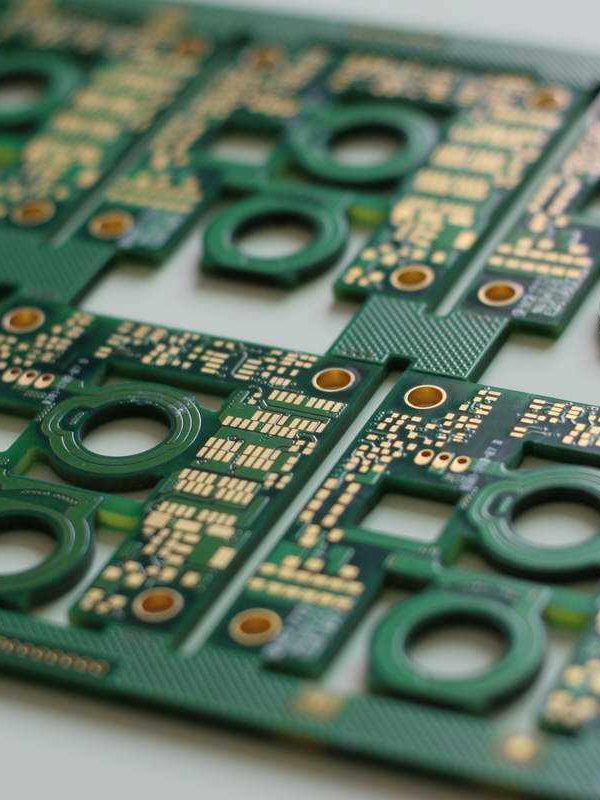

Lingkey's Medical PCB Products

Lingkey has successfully supplied medical PCB solutions for a range of applications. Our products support devices like heart rate monitors, ultrasound systems, and infusion pumps, which require precision and reliability. Examples of our offerings include advanced PCBs for MRI systems, portable glucose meters, and surgical equipment. Each product is meticulously designed and tested to ensure it performs at the highest level in critical medical settings.

High reliability

Medical devices are often used in critical diagnostic and life support applications, and any failure may have a serious impact on the patient's health. Therefore, medical PCBs require extremely high reliability.

Anti-electromagnetic interference (EMI)

Hospitals and clinics often have a variety of electronic devices running at the same time, so medical PCBs need to have good anti-electromagnetic interference performance to ensure signal accuracy and normal operation of equipment.

Biocompatibility

Especially for those medical devices that are in direct contact with patients, their PCB materials must be biocompatible and not cause any adverse biological reactions.

Strict certification standards

The manufacturing and design of medical PCBs must comply with international medical standards, such as ISO 13485, which is a quality management system standard specific to the medical device industry.

To meet the stringent requirements of the medical industry

The manufacturing of medical PCBs involves a variety of advanced technologies and materials:

High-performance materials

Use high-TG materials and high-frequency materials to improve the thermal stability and signal integrity of the PCB.

High-precision manufacturing

Advanced manufacturing technologies such as laser drilling and precision etching are used to ensure high precision and high performance of PCBs.

Rigorous testing and verification

Each medical PCB needs to undergo multiple tests, including electrical testing, thermal testing, and vibration testing, to ensure its reliability under various conditions.

Trust us

Lingkey’s delivery process ensures that every medical PCB we produce meets our high standards while exceeding client expectations.

Lingkey takes pride in playing a pivotal role in medical PCB manufacturing, delivering high-quality products that empower medical professionals and enhance patient outcomes. With an unwavering focus on precision, reliability, and innovation, we are dedicated to providing exceptional PCB solutions for the health care industry.