High-frequency PCB Design and Manufacturing Services

High-frequency PCBs are PCBs designed specifically for use in high-frequency (usually above 500 MHz) and microwave (usually above 2 GHz) applications.

Why Choose Lingkey

Here are some of the reasons why you should choose Lingkey as your High-frequency PCB manufacturer:

01

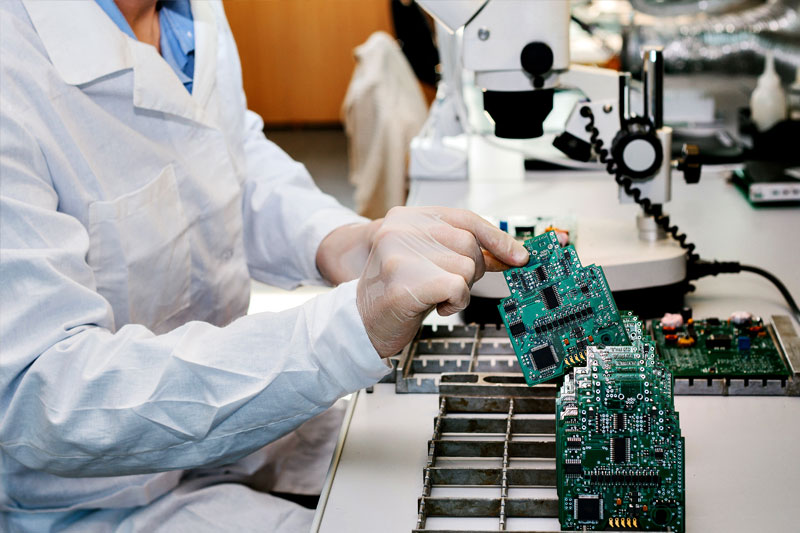

We possess extensive expertise in manufacturing High-frequency PCB solutions for a diverse range of industries.Our state-of-the-art production facilities enable us to manage even the most complex High-frequency PCB designs with utmost precision and consistency.We ensure rigorous quality testing for every High-frequency PCB to guarantee optimal performance and enduring reliability.

Our High-frequency PCB solutions, manufactured with proven reliability, are trusted across various sectors, including telecommunications, aerospace, automotive, and medical devices. These industries depend on our precision-engineered PCBs to achieve efficient, high-speed signal transmission which speaks volumes about the quality of our products.

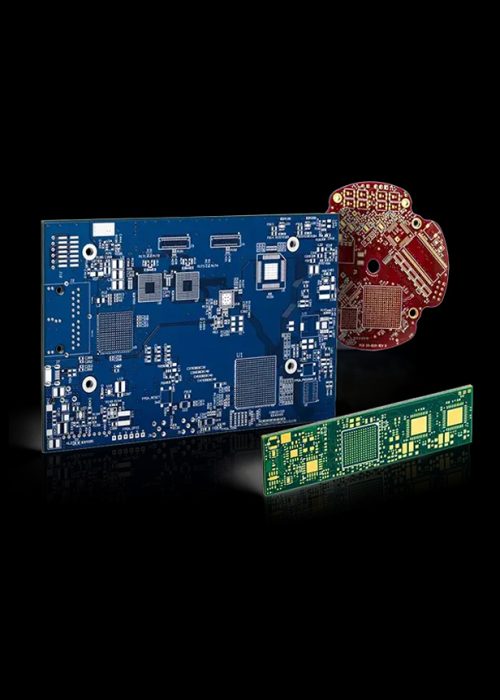

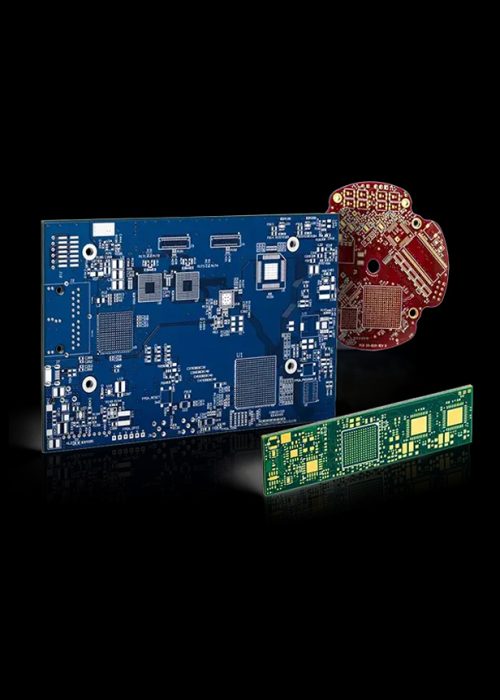

Diverse Range of High-frequency PCB Options

A high-frequency PCB is a specialized circuit board tailored for rapid signal transmission and superior electrical performance. This type of PCB can be further divided into some different types, including:

Single-Layer PCBs

Comprising a single layer of conductive material, typically copper, these PCBs are ideal for straightforward circuit designs. These are cost-effective and offer straightforward signal routing. They are commonly used in RF (Radio Frequency) applications.

Double-Layer PCBs

eaturing conductive layers on both sides, these PCBs facilitate more intricate circuit designs.n. They provide better signal routing and are commonly used in advanced communication devices and network systems.

Multilayer PCBs

Constructed with multiple layers of conductive material, typically separated by insulating layers, these PCBs are designed for high signal integrity which makes them ideal for satellite systems and advanced radar technologies.

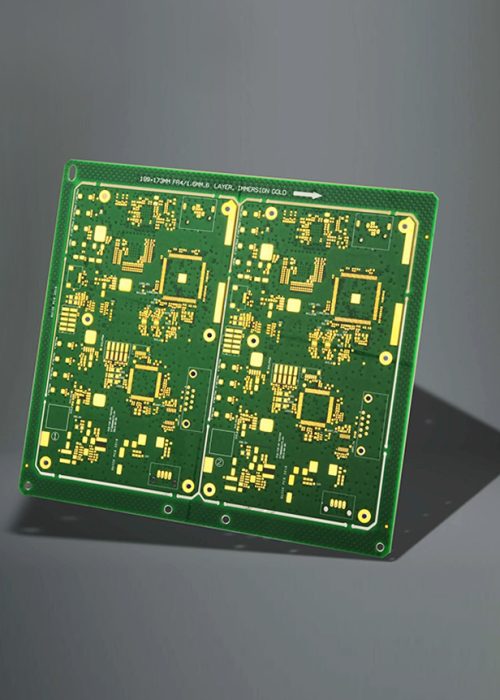

What is High Frequency PCB

High-frequency PCBs are PCBs designed specifically for use in high-frequency (usually above 500 MHz) and microwave (usually above 2 GHz) applications. This type of PCB has special considerations in material selection, design, and manufacturing processes to ensure that the integrity and performance of signal transmission are not disturbed during high-speed transmission. Since high-frequency signals have extremely strict requirements on PCB materials and manufacturing processes, the manufacture of high-frequency PCBs faces multiple challenges. This includes material selection, precise manufacturing processes, and cost control. The manufacturing cost of high-frequency PCBs is usually higher than that of conventional PCBs because the materials and manufacturing technologies required are more advanced and complex.

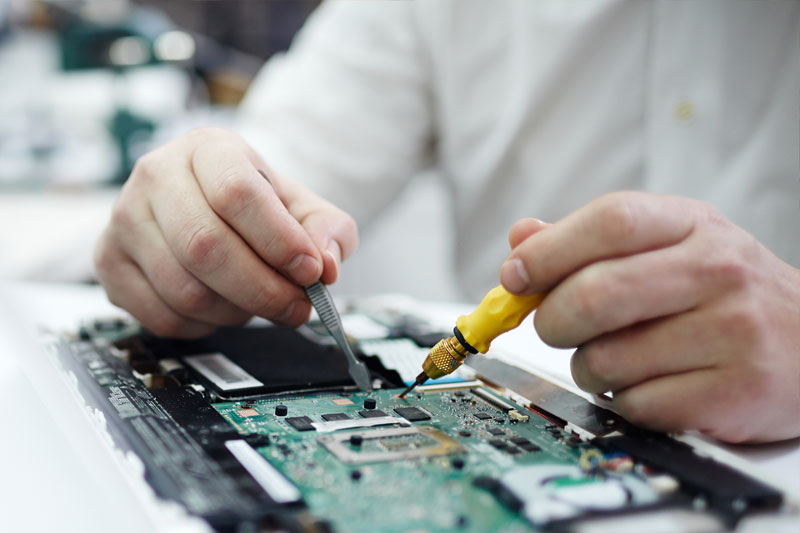

As a specialist in High-frequency PCB manufacturing, we leverage state-of-the-art process technologies to distinguish ourselves from competitors. Employing the latest technologies, including precision laser drilling, automated copper plating, and high-accuracy etching, we ensure that each High-frequency PCB design adheres to the strictest quality and manufacturing standards. Moreover, our sophisticated lamination techniques maintain layer integrity and make sure that there is no signal loss no matter how demanding a circuit is.

Why Choose Lingkey’s High-frequency PCB?

At Lingkey High-frequency PCB manufacturer, our High-frequency PCB solutions are reliable and deliver outstanding performance. Our boards are engineered with advanced thermal management, minimal dielectric loss, and superior signal integrity, ensuring seamless system operation.We utilize meticulously selected materials to minimize signal attenuation and uphold stable performance across various platforms. Furthermore, our High-frequency PCB designs are optimized to mitigate electromagnetic interference (EMI), enhancing system reliability.

Peculiarity

01

Material usage

High-frequency PCBs are usually manufactured using materials with low dielectric constant (DK) and low dielectric loss (DF). Common high-frequency PCB materials include PTFE (polytetrafluoroethylene, commercial names such as Teflon), FR-4 High Performance, Rogers series materials, etc. These materials can provide better signal transmission performance and lower signal loss.

02

Design considerations

In high-frequency applications, the design of PCBs must take into account signal integrity issues such as impedance control, signal loss, and electromagnetic interference (EMI). Specific line layouts and stacking structures must be used during design to reduce signal degradation and crosstalk.

03

Manufacturing accuracy

The manufacturing process of high-frequency PCBs requires higher accuracy, including line width control, hole position accuracy, and interlayer alignment. Any slight deviation may lead to performance degradation.

Technical Capabilities

Offering

Finished board thickness (thinnest – thickest)

Minimum Hole Diameter

Minimum line width/spacing

Maximum board size

Impedance control

Surface treatment process

Processing materials

1-48 layers

0.008″ ~ 0.24″

6mil (0.15mm)

3-4 mil (0.076-0.10mm)

Single and double layer 22″x 43″ (550 x 1100mm) Multilayer 22″x 25″ (550mm x 640mm)

± 10%

oxidation resistant OSP, tin spraying

FR4 (Sangyi, KB, International), high TG (TG150, TG170)