Table of Contents

- Introduction to Soldering and Its Importance in Electronics

- Understanding Solder for Circuit Boards:Definition and Purpose

- What is Solder for Circuit Boards?

- Understanding the Different Types of Solder for Circuit Boards

- Solder Forms and Their Applications

- The Top 8 Best Solders for Circuit Boards (Product Guide)

- Lead vs. Lead-Free Solder: Key Differences Explained

- Factors to Consider When Selecting the Right Solder for Your Circuit Boards

- Essential Tips for Successful Soldering on Circuit Boards

- Solder Flux: What It Is and Why It’s Important

- Troubleshooting Soldering Problems

- Safety Precautions When Working with Solder

- Maintenance Tips for Solder and Tools

- Frequently Asked Questions: Soldering Circuit Boards

- Additional Resources and Where to Buy

- Conclusion: Selecting the Right Solder for Your Next Circuit Board Project

Introduction to Solder and Its Importance in Circuit Board Electronics

Have you been inspired by the functionality of modern gadgets? Solder deserves credit as it connects electronic components to circuit boards while creating electrical pathways and providing mechanical strength – essential elements to successful electronic projects.

Choose the Right Solder With so many solder materials available today–ranging from lead-based solders, lead-free solders, and specialty alloys–it can be difficult to select the appropriate solder material. But choosing wisely can have lasting impacts on durability, safety, and performance of PCBs; know Your Type/Technique When Applying Solder Wire or Solder Paste to Produce Robust PCBs

This ultimate guide to the best solder for circuit boards will help you navigate all options, explain how solder provides stable joints, and guide you in making the right selection for your next project.

Understanding Solder for Circuit Boards: Definition and Purpose

Solder is a specialized metal alloy designed to create strong, conductive bonds between electronic components and the copper traces on a circuit board. When heated, solder melts and flows around component leads, then solidifies as it cools to form both an electrical connection and mechanical support. The primary purpose of solder in circuit boards is to ensure stable, low-resistance pathways for electrical signals and power, enabling the circuit to function as intended. Solder also physically secures components, protecting them from movement due to vibration or handling. Used correctly, solder results in shiny, durable joints that are essential for both reliability and performance. Choosing the correct solder type for your circuit board—whether it’s lead-based, lead-free, or a specialty alloy—is key to achieving long-lasting electronic assemblies and minimizing the risk of circuit failure.

What is the Best Solder for Circuit Boards?

Solder is available in many compositions, but at its core, solder is a metal alloy that fuses together metal surfaces. When you’re soldering circuit boards, this alloy is melted and flows between component leads and copper pads. As solder cools, it solidifies to create a stable, conductive bond.

A successful solder joint should look bright and concave, rather than dull and cracked–an indicator of its strength. Solder should flow easily over surfaces for maximum connection while preventing excess solder from creating shorts or weak joints.

Solder is a dream come true for electronic enthusiasts, transforming heaps of components into functional circuits.

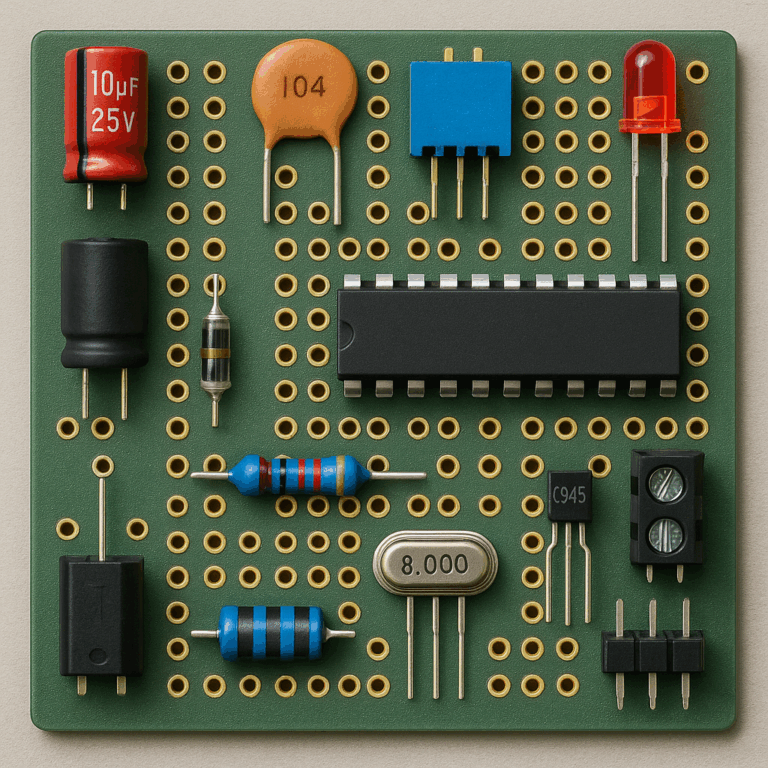

Choosing the Right Solder: Forms of Solder

- Solder Wire

- The most common solder for hand-assembly.

- Solder wire offersvarious thicknesses; choosethicker solder(0.8-1mm) for large joints andsmall solder(0.3-0.5mm) for fine-pitch SMT.

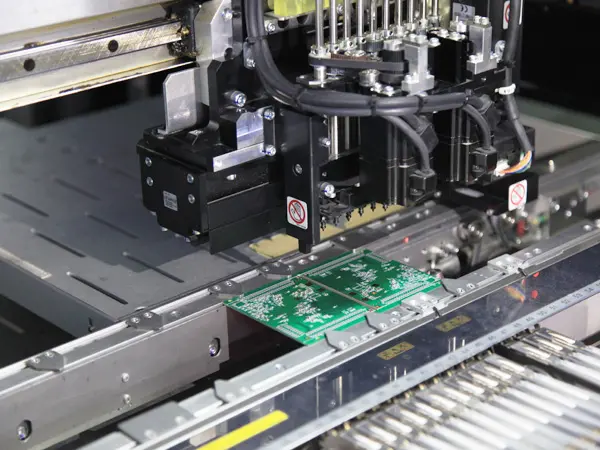

- Solder Paste

- Used heavily in SMT.Solder paste allowsautomated and precise distribution: amixture of tiny solder particles and fluxis applied to pads before component placement.

- Solder paste is appliedusing a stencil, andmolten solderforms reliable joints in a reflow oven.

- Solder Bars

- The industry standard for wave soldering, providing economies of scale for high-volume PCB work.

| Solder Form | Feature | Application |

| Solder Wire | Manual work, comes in various diameters | Hand soldering |

| Solder Paste | Mixture oftiny solder particles and flux Automated, precise deposition |

SMT, reflow |

| Solder Bars | Bulk, solid, melted en masse | Wave soldering, mass assembly |

Understanding the Different Types of Solder for Circuit Boards

When selecting the right solder, knowing your alloys is vital. There are two types of solder primarily used: lead-based and lead-free solder. Each has unique properties and uses:

Lead-Based Solders (Tin-Lead Solder, SnPb)

- Classic tin-lead solder(e.g., Sn63/Pb37, Sn60/Pb40), long favored for its low melting point of the solder (~183°C for Sn63/Pb37).

- Melting the solder alloyis easy, resulting in excellent wetting properties and brilliant, durable joints.

- Still vital in aerospace, medical, and military projects due to unmatched stability.

Lead-Free Solder

- Popular formulations: Tin-Silver-Copper (SnAgCu/SAC305), Tin-Copper (SnCu), Tin-Bismuth (SnBi).

- Higher melting point of the solder(217–227°C), but solder is a reliable and RoHS-compliant option for all consumer products.

- Lead and lead-free soldermay look alike, but use the one that best aligns with your compliance and temperature needs.

Specialty/Silver Solders

- Silver solders or alloys like Harris Stay-Brite Silver Solder offershigh strength at low temperatures—ideal for sensitive, high-value boards.

- Silver solder offers the benefitsof heightened conductivity and strength.

Common solder: The most widely used are Sn63/Pb37 (for legacy and repairs) and SAC305 for new, compliant boards.

Solder Forms and Their Applications

Let’s get practical. The selection of solder—wire, paste, or bar—impacts both ease and outcome.

Solder Wire

- High-quality solder wire makes hand soldering a dream come true.

- Consider the diameter of the solder wire: thicker solder for connectors, small solder for SMD.

- Rosin core, like SRA Soldering Products Rosin Core Solder, helps remove oxidation and make strong, shiny joints.

Solder Paste

- A mixture of tiny solder particles and flux—with particle size (often referred to as “Type 3,” “Type 4,” etc.) tailored for your process.

- Solder paste allowsrapid, consistent, and automated assembly.

- When solder paste is applied, controlled heating ensures uniform molten solderand robust joints.

Solder Bars

- Used in wave soldering. Not for hand work, but essential for large-scale PCB (printed circuit board)

The Top 8 Best Solders for Circuit Boards (Product Guide)

Jumpstart your project with these top 8 best options. Each is a tested, respected performer:

| Solder Brand/Product | Solder Alloy | Features | Best For |

| Kester 44 Rosin Core Solder | Sn63/Pb37 | Clean solder is a dream, fast wetting | General hand soldering, repair |

| Alpha Fry AT-31604 | Sn60/Pb40 | Great for hobby, strong flow | Beginners, DIY |

| MG Chemicals 63/37 No Clean Solder | Sn63/Pb37 | Minimal residue, easy rework | Prototyping, sensitive boards |

| WYCTIN 60/40 Solder Wire | Sn60/Pb40 | Economic, consistent | Everyday projects |

| SRA Soldering Products Rosin Core Solder | Sn63/Pb37 | Soldering products rosin core solder | Hobby/educational |

| Cardas Soldering Wire | High-silver | Audiophile-grade | High-fidelity audio, specialty |

| Harris Stay-Brite Silver Solder | Silver alloy | Harris Stay-Brite Silver Solder offers low temp, strong bonds | Heat-sensitive, specialty circuits |

| Worthington 60/40 Solder Wire | Sn60/Pb40 | Widely available, reliable flow | Educational, DIY, bulk use |

Why these? Each of these solders, from Kester solder wire to Harris Stay-Brite Silver Solder, boasts a track record for creating durable, reliable solder joints in applications ranging from SMT assembly to audio circuits. Solder wire allows flexibility when hand soldering; silver solder offers improved conductivity and reduced joint fatigue.

Lead vs. Lead-Free Solder: Key Differences Explained

When deciding between lead-based and lead-free solder, it’s important to consider regulatory requirements, environmental impact, and technical needs. Here’s a helpful comparison:

| Feature | Lead-Based Solder (SnPb) | Lead-Free Solder (SAC, SnCu, SnBi) |

| Melting Point of Solder | ~183°C (Sn63/Pb37, eutectic) | ~217–227°C (varies by alloy) |

| Workability | Flows easily, forgiving | Requires precise temperature control |

| Reliability | Excellent for repairs, legacy | Reliable with the right process |

| Environmental Impact | Contains toxic lead | RoHS-compliant, eco-friendly |

| Where Used | Repair, aerospace, highly reliable PCBs | All new, consumer, and industrial products |

Pro Tip: The two types of solder are not interchangeable for regulated projects. Always select the one that best aligns with safety and compliance needs. Modern hobbyists often prefer lead-free, but pros repairing vintage equipment may reach for tin-lead solder.

Factors to Consider When Selecting the Right Solder for Your Circuit Boards

When making your selection of solder, assess these key factors:

Solder Alloy and Applying

- Solder material: Choose between Sn63/Pb37, SAC305, and others according to reliability and regulation.

- Solder should flowsmoothly and create robust, shiny connections.

Diameter of the Solder Wire

- Thicker solder(0.8–1mm): for connectors and large pads.

- Small solder(0.3–0.5mm): for SMD and fine electronics.

Flux Type

- Rosin core(e.g., Kester 44, SRA Soldering Products Rosin Core Solder): Quick, clean joints.

- No-clean: Minimal residue, suitable where extra cleaning is not possible.

Melting Point of the Solder

- Sensitive parts? Choose a low-melting alloy like tin-bismuth.

- High-performance? Use high temp, lead-free solder.

Amount of Solder Applied

- Too little can result in weak solder joints; too much can cause shorts or solder balls.

- Always use just enough so that the solder providesa strong, shiny joint and fills the pad completely without overflowing. The angle to fit the circuit can influence how molten solder flows—position your board so solder flows naturally into the joint and fit the circuit board holes

Remove Oxidation and Excess Solder

- Always remove oxidation and excess solderusing braid (solder wick) or a solder sucker for good rework and reliable repairs.

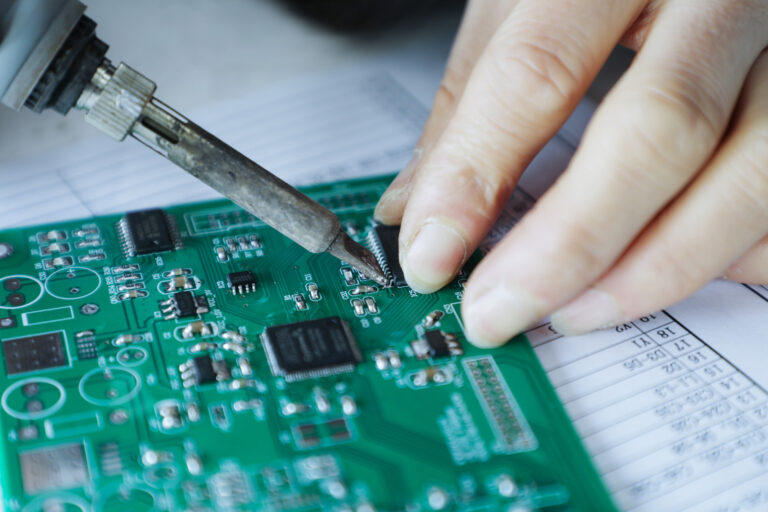

Essential Tips for Successful Soldering on Circuit Boards

- Clean Solder Is a Dream: Always use clean, well-maintained solder and tools.

- Use a Good Soldering Iron: Adjustable temperature and quality tips are critical—ensure full melting of the solder alloy.

- Solder Wire or Solder Paste: Use solder wirefor repairs and through-hole work, or solder paste for automated SMT.

- Use Just Enough Solder Material: Don’t overdo it; too much causes bridges, too little means weak solder joints.

- Solder Sucker for Cleanup: Essential for desktops to “undo” mistakes and control amount of solder applied.

- Watch for Solder Balls: Common if solder is appliedtoo rapidly or at excessive temperature.

Solder Flux: What It Is and Why It’s Important

Flux removes oxidization and prepares the PCB for strong metal-to-metal bonding. Rosin core, no-clean, and water-soluble variants each have their place based on cleaning requirements and board sensitivity.

- For many, rosin core solderlike Kester 44 is the solder is a dream come true: it eliminates a cleaning step and ensures bonds are resilient and conductive.

Troubleshooting Soldering Problems

- Excess Solder: Use a solder sucker or wick to clean up.

- Cold or Dull Joints: Reheat with enough flux for better flow.

- Solder Balls: Indicates too much solder or too rapid heating.

Safety Precautions When Working with Solder

- Ventilation always! Whether you use lead-based or lead-free solder, fumes can be hazardous.

- Wear eye protection and avoid prolonged skin contact.

- Use fume extractors and always remove oxidation and excess solderwaste responsibly.

Maintenance Tips for Solder and Tools

- Store solder in a cool, dry place.

- Wipe soldering iron tips clean frequently.

- Discard old solder, especially if it’s dirty or severely oxidized.

Frequently Asked Questions: Soldering Circuit Boards

What’s the safest solder to use?

For most users, lead-free solder is recommended. For legacy or specialty work, tin-lead solder may be permitted.

Solder Paste or Solder Wire?

Use solder wire or solder paste suited to your assembly process—wire for hand, paste for reflow/SMT.

How to handle excess solder or rework?

Use a solder sucker or wick to pull excess from the board.

Conclusion: Selecting the Right Solder for Your Next Circuit Board Project

Selecting the right solder for your circuit will set you up for success, whether you’re a DIY hobbyist or a professional. Consider when selecting solder: alloy, form, flux, melting point, and application method to ensure reliable solder joints every time. Remember, the solder to use is the one that best aligns with your requirements for durability, compliance, process, and component sensitivity—don’t just reach for the most common solder, but pick what fits your project!