Your Partner in High-Quality SMT Assembly

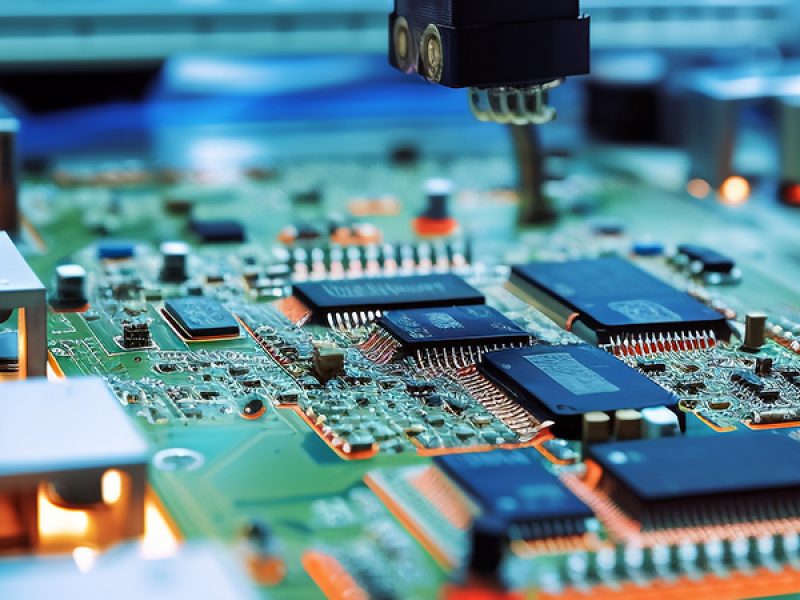

Surface Mount Technology (SMT) assembly is the fundamental process in modern electronics manufacturing. It involves the precision placement of electronic components onto a printed circuit board (PCB) using automated machinery, resulting in compact, efficient, and high-performance electronic devices. The integrity of the SMT assembly process is paramount to ensuring reliable connections and optimal functionality. At Lingkey PCBA, we specialize in providing exceptional SMT assembly services, transforming your innovative designs into tangible, working realities.

Common SMT Assembly Product Types

Our SMT assembly capabilities are remarkably versatile, spanning a broad range of product types. We routinely work with various products including consumer electronics, from smartphones, tablets, wearables, and home automation devices to industrial controls like circuit boards for manufacturing equipment, robotics, and automation systems. Moreover, we produce vital components for medical devices, including diagnostic tools, patient monitoring equipment, and medical imaging systems, as well as automotive electronics like in-car entertainment systems, control units, and sensor modules.

What is SMT Assembly?

Fundamentally, SMT assembly is the method of mounting surface mount components (SMCs) directly onto the surface of a PCB. This approach contrasts with the older through-hole technology. The process initiates with the application of solder paste, which is followed by the meticulous placement of components using advanced pick-and-place machines. The process culminates with reflow soldering, creating secure and permanent electrical connections. This highly precise method allows for denser board designs and greater manufacturing efficiency, leading to smaller and more powerful electronic devices that drive innovation across numerous industries.

Lingkey’s SMT Assembly Process

Automated Solder Paste Printing

Uses precision stencils and printers for consistent solder paste application.

Automated Optical Inspection (AOI)

Uses camera-based systems to detect assembly defects.

High-Speed Pick-and-Place Machines

Employs advanced robotic placement technology for accurate and efficient component placement.

X-Ray Inspection

Provides in-depth inspection of solder joints, particularly for BGA and other hidden components.

Multi-Zone Reflow Ovens

Ensures consistent and precise solder reflow profiles for optimal joint integrity.

Lingkey’s Advantages in SMT Assembly

Common SMT Assembly Questions

SMT (Surface Mount Technology) involves mounting components directly onto the surface of the PCB. It is smaller, more efficient, and often automated. In contrast, through-hole technology requires component leads to be inserted into drilled holes in the PCB and soldered on the opposite side. It is larger, more robust, and often involves some manual assembly processes.

For SMT assembly, we typically require Gerber files for the PCB layout, a Bill of Materials (BOM) listing components and specifications, and a Pick and Place file that provides coordinates for component placement.

Yes, we offer flexible SMT assembly services that cater to prototypes, small batches, and high-volume production runs.

Our quality control measures include Automated Optical Inspection (AOI), X-Ray inspection for hidden solder joints, rigorous material checks, and thorough process monitoring.

Advantages of SMT assembly

01

High-density assembly

allows more components to be installed in a limited space, suitable for the miniaturization needs of modern electronic devices.

02

Automated production

highly automated production processes improve production efficiency and consistency and reduce labor costs.

03

Improved performance

reduces the length and connection points of the circuit, which helps to increase signal transmission speed and reduce interference.

04

Flexible design options

supports components of various sizes and shapes, providing designers with greater flexibility.

Industries Served by Lingkey's SMT Assembly Services

Consumer Electronics:Lingkey’s electronics SMT expertise is crucial for the consumer electronics sector, where they manufacture high-quality products for diverse applications. This involves a wide range of devices, from everyday gadgets to specialized consumer goods, requiring precision and reliability.

Automotive Industry:Lingkey supports advanced systems within the automotive industry by providing dependable electronics SMT These services are critical for creating reliable components for vehicles, ensuring both performance and safety for various automotive applications.

Industrial Equipment:Given that the text implies more than just consumer and automotive sectors, and given the general need for robust and reliable electronics in industrial contexts, it’s logical to infer that Lingkey serves the Industrial Equipment sector. This involves producing electronics SMT for factory automation systems, control panels, and other heavy-duty machinery, demanding consistent performance and durability in harsh environments.

The main steps of SMT assembly include

01

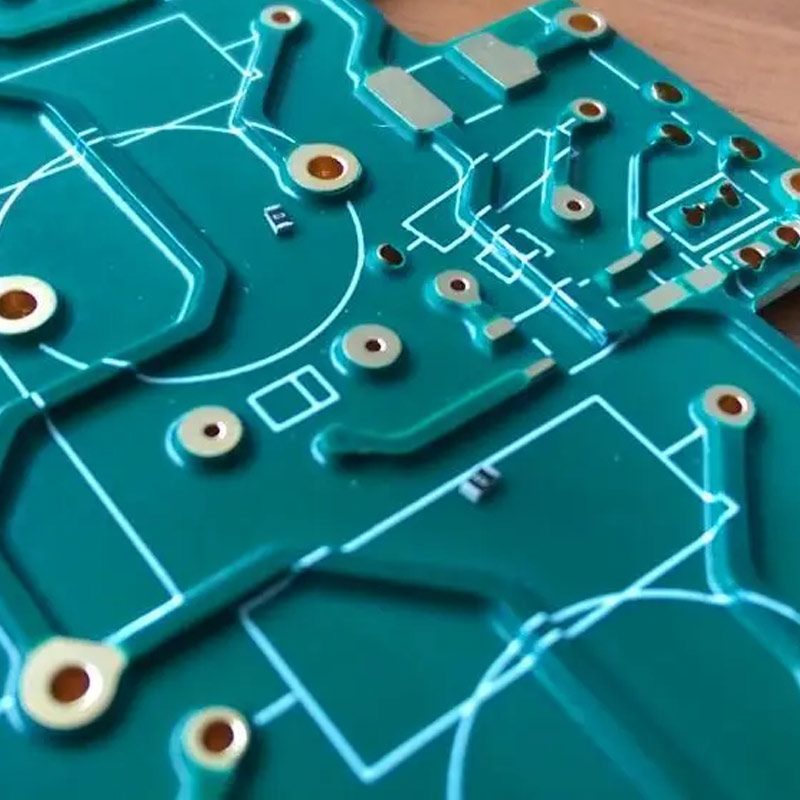

PCB design and manufacturing

The design stage needs to ensure that the PCB is suitable for SMT assembly, including appropriate pad design, marking, and protective layer.

During the manufacturing stage, the PCB surface needs to be properly treated, such as HASL or ENIG, to ensure good soldering performance.

02

Printing solder paste

Solder paste is printed on the corresponding pads of the PCB through a steel screen. Solder paste mainly consists of metal powder (such as tin) and flux, which is responsible for forming solder joints during the reflow process.

03

Placing components

Electronic components are precisely placed on pads coated with solder paste using a placement machine. These machines are usually equipped with high-precision camera systems to ensure that components are accurately aligned.

04

Reflow soldering

The assembled PCB enters the reflow soldering oven, where the solder paste is heated to the melting point and cooled to solidify in a controlled heating environment to form a strong electrical connection.

The reflow soldering process includes preheating, heat activation, reflow, and cooling stages, and the temperature and time of each stage need to be precisely controlled.

05

Inspection and Testing

After soldering is completed, automated optical inspection (AOI) and X-ray inspection are usually used to ensure the quality of solder joints and correct placement of components.

Functional testing and electrical testing may also be performed to ensure that the assembled PCB works as expected.