Advantages

Suitable for low-frequency applications

For low-frequency applications, the electrical performance of DIP packaging is usually fully sufficient and more cost-effective. In these applications, electrical interference and signal

Simplicity and low cost

The assembly process of DIP components is relatively simple, usually only requiring the pins to be inserted into pre-drilled holes on the PCB and fixed by wave soldering or hand soldering. This assembly method does not require complex equipment or highly skilled operations, so the cost is relatively low. In addition, the manufacturing and packaging costs of DIP components are also generally lower than those of higher-density SMT components.

Convenience of replacement and maintenance

DIP components are easy to insert and remove from the socket, which makes maintenance and upgrades simple. In many applications, such as test equipment or modular electronic systems, users can easily replace or upgrade DIP components without complicated soldering work.

Easy manual soldering and rework

The pins of DIP components are thicker and the spacing is wider, making manual soldering and rework easy. This is especially important for prototyping, education, DIY projects, and small-batch production, as these applications often rely on manual assembly and debugging.

High heat resistance

DIP components do not need to undergo a high-temperature reflow process during manufacturing, which allows them to use a wider variety of materials, including some semiconductor materials that are sensitive to high temperatures. This makes it possible to use specific materials in specific applications.

Strong mechanical stability

Since the pins of DIP components pass directly through the PCB and are soldered, this provides strong mechanical support and stability for the components. This stability is an important advantage for applications that may be subjected to vibration or mechanical stress, such as some industrial and consumer electronics.

Compatibility and standardization

DIP packaging has a long history in the electronics industry, and many standards and equipment designs are based on DIP packaging. Therefore, components using DIP packaging can ensure good compatibility with existing systems.

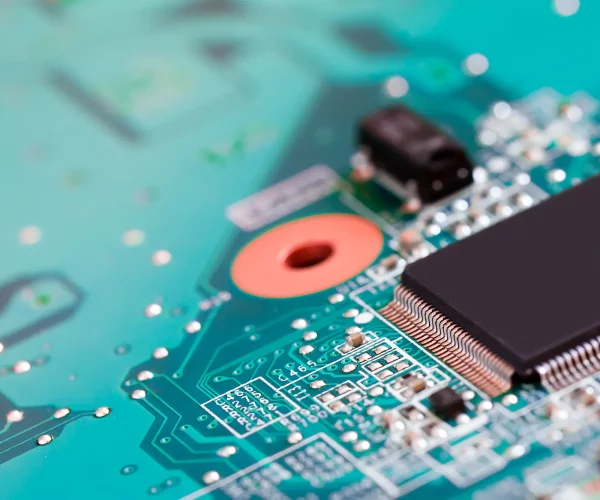

Your Trusted DIP Circuit Board Manufacturer

DIP PCB assembly consists of mounting components with two parallel rows of pins that fit into matching holes on a printed circuit board (PCB). This through-hole technology ensures strong mechanical bonds, making it ideal for a wide range of applications.

DIP circuit boards are widely used in legacy systems and modern designs that require repair-friendly and stable connections. Unlike surface-mount technology, DIP assembly offers a straightforward and hands-on approach, enabling ease of testing and maintenance.

DIP circuit boards and DIP PCB assembly are used across various industries, including consumer electronics, automotive systems, and industrial equipment. They are ideal for educational tools, prototyping projects, and legacy systems due to their durability and ease of repair.

Lingkey's Process

Lingkey is dedicated to providing top-notch DIP PCB assembly services. Our process incorporates the latest technology and expert craftsmanship to deliver high-quality results.

Precise Component Placement

Automated and manual techniques ensure accurate alignment of pins and holes.

Comprehensive Testing

Each board undergoes rigorous functional and quality tests to ensure optimal performance.

Wave Soldering Expertise

This method provides efficient and consistent soldering for through-hole components.

Custom Solutions

We tailor our assembly processes to meet specific client requirements, ensuring the best fit for every project.

Features of DIP Circuit Boards

Prominent features of DIP circuit boards include:

Why Choose Lingkey for DIP PCB Assembly?

Lingkey offers numerous advantages that make us a trusted partner for DIP circuit board solutions:

- Experienced Team:Decades of experience in PCB assembly ensure superior craftsmanship.

- State-of-the-Art Equipment:Advanced tools enable precise and efficient assembly.

- Customizability:We provide tailored solutions to fit diverse applications.

- Quality Assurance:Rigorous testing guarantees top-notch reliability.

- Competitive Pricing:Affordable services without compromising quality.

Common Questions

DIP circuit boards provide stronger mechanical bonds, easier repairs, and a more straightforward assembly process compared to surface-mount technology.

We use advanced soldering techniques, precise component placement, and comprehensive testing to maintain the highest quality standards.

Yes, the DIP circuit board remains relevant for modern electronics that require durability, repairs, and simple designs.

Process

01

PCB Design

First, design the PCB layout, including all circuit component locations, connection paths (traces), pads (areas for soldering components), and any necessary test points. For DIP components, the design needs to ensure that there are appropriate holes for inserting DIP pins.

02

PCB Manufacturing

Manufacture the PCB according to the design drawings. This includes material selection, multi-layer lamination, drilling, circuit pattern printing, electroplating, cutting, and final cleaning.

03

Component Procurement

Purchase all the required electronic components, including DIP-packaged integrated circuits, resistors, capacitors, and any other necessary components.

04

PCB Pretreatment

Before starting assembly, clean the PCB to ensure that there is no dust, grease, or other contaminants. This step is very important to ensure good soldering quality.

05

Component Insertion

Properly insert the pins of the DIP component into the pre-drilled holes on the PCB manually or using a semi-automatic insertion machine. Make sure all components are properly placed and oriented.

06

Wave Soldering

The PCB board with components is passed through a wave soldering machine, which is a process that passes a liquid solder bath to automatically form solder joints along the component pins and PCB pads. Wave soldering is a fast and efficient soldering method suitable for through-hole components.

07

Manual Soldering

For some parts that are delicate or difficult to handle by wave soldering, manual soldering may be required. This is usually done by experienced technicians using a soldering iron.

08

Inspection and Cleaning

After soldering is completed, the PCB is visually inspected, or automatic optical inspection (AOI) equipment is used to check the soldering quality. After the inspection, it is cleaned to remove any residual solder paste or flux.

09

Testing

Functional testing and electrical testing are performed to ensure that all circuits work as designed and there are no shorts or breaks. Testing may include point-to-point electrical connectivity testing and functional verification.

10

Final Inspection and Packaging

Finally, a final inspection is performed to ensure that all assembly steps meet quality