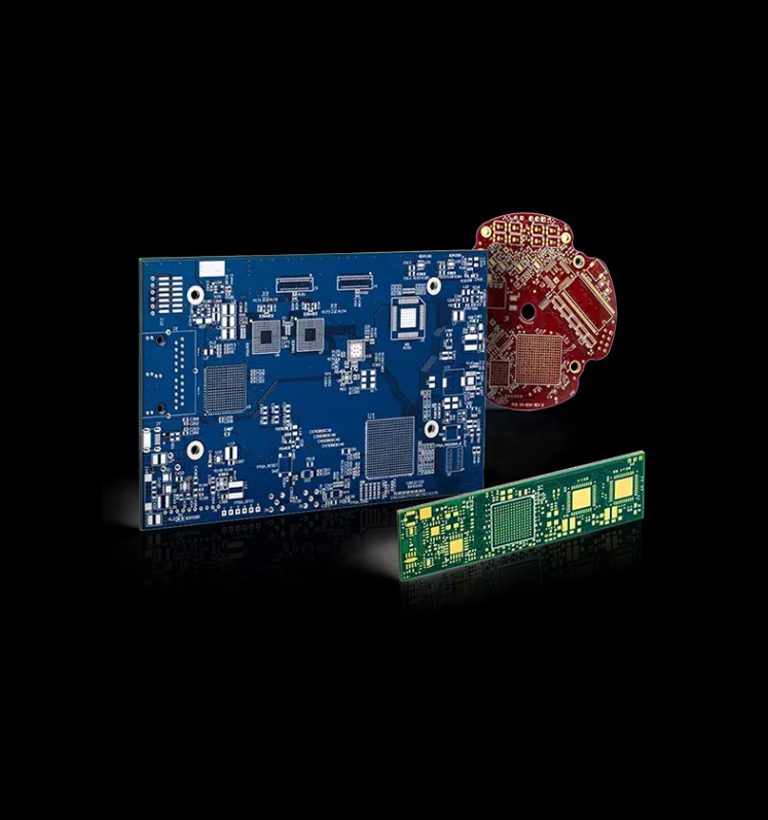

One Stop Service

The company's basic information about this service

Design and layout

We can design PCB layout schematics, and circuit diagrams for you. We can also optimize the circuit schematics you provide to reduce costs and improve production efficiency.

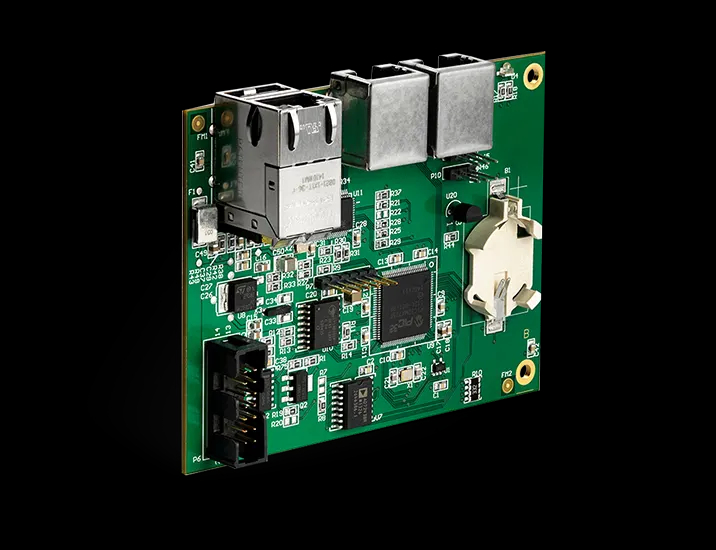

PCB assembly

We will solder the manufactured PCBs and components, including surface mount technology (SMT) and through-hole technology (THT).

Component procurement

We can purchase all the electronic components required according to the BOM (Bill of Materials).

Inspection and quality control

After the assembly is completed, we will conduct a series of tests such as automatic optical inspection (AOI), X-ray inspection, and functional testing to ensure that the component position, welding quality, and final function of each circuit board meet the predetermined standards.

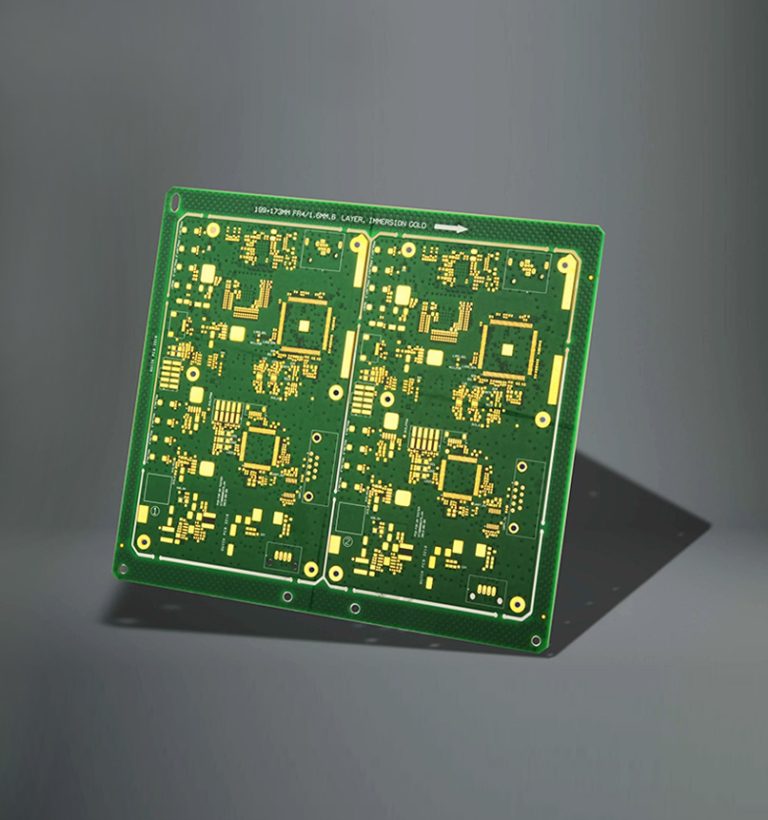

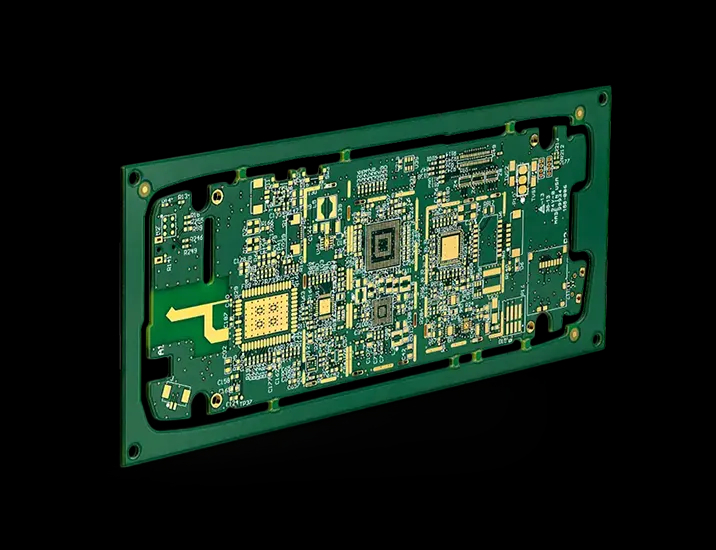

PCB manufacturing

After the data is confirmed, we will put the PCB into production, which includes a series of manufacturing processes.

Logistics and after-sales support

After all production and inspection work is completed, we will arrange the delivery of the products and provide a series of after-sales services such as technical consultation, product maintenance, etc.

What we can do for you

Why Choose Lingkey for

PCB One-Stop Service?

Lingkey’s PCB one-stop service is designed to take the stress out of the PCB development process. With all services under one roof, you get better quality control, faster turnaround times, and a dedicated team focused on making your project a success. Our one-stop PCB assembly solutions offer unmatched reliability and efficiency, helping you stay ahead in a competitive market.

Lingkey PCB One-Stop Service: Comprehensive PCB Solutions

In today’s fast-paced electronics industry, having a reliable PCB one-stop service is more crucial than ever. At Lingkey, we understand the need for streamlined processes and efficient communication. The concept of PCB one-stop service brings everything under one roof, reducing lead times and potential miscommunication between different suppliers. By providing a complete solution, Lingkey helps customers avoid the complexity of dealing with multiple vendors, ensuring a smoother journey from design to finished product.

Challenges in One-Stop PCB Services and How Lingkey Solves Them

While PCB one-stop service offers many benefits, it can also come with its challenges, such as quality control, communication gaps, and longer lead times if not managed effectively. Lingkey is here to tackle these challenges head-on:

Quality Control

Maintaining consistent quality throughout the process can be challenging. At Lingkey, we conduct rigorous quality checks at every stage to ensure that each board meets international standards.

Communication Gaps

With so many processes involved, communication can easily break down. Lingkey solves this by offering dedicated project managers who keep you informed at every stage of the process, ensuring that your requirements are understood and met.

Lead Time Management

Handling everything in one place can sometimes lead to bottlenecks. Lingkey optimizes the workflow to prevent delays, ensuring a smooth transition from design to assembly with our one-stop PCB assembly solutions.

Services Provided by Lingkey

Lingkey’s PCB one-stop service includes everything you need to bring your ideas to life. Here’s what we offer:

Design and Prototyping

Our experienced engineers work closely with you to design and prototype your PCB, we can also optimize the circuit schematics you provide to reduce costs and improve production efficiency, ensuring it meets your specifications and is ready for manufacturing.

Component procurement

We can purchase all the electronic components required according to the BOM (Bill of Materials).

Manufacturing

After the data is confirmed, we will put the PCB into production, and handle multi-layer PCB manufacturing with advanced equipment, which includes a series of manufacturing processes, ensuring high precision and reliable boards.

Assembly

Our one-stop PCB assembly service includes surface mount technology (SMT) and through-hole assembly to meet the specific requirements of your project.

Testing and Quality Assurance

After the assembly is completed, we will conduct a series of tests such as automatic optical inspection (AOI), X-ray inspection, and functional testing to ensure that the component position, welding quality, and final function of each circuit board meet the predetermined standards.

Logistics Support

After all production and inspection work is completed, we also provide logistics support to ensure timely delivery of your products, making the entire process seamless from start to finish, and provide a series of after-sales services such as technical consultation, product maintenance, etc.

One Stop Service

“One Stop Service” is a comprehensive service that can provide you with a complete service solution from start to finish, so that you can get all the services you need from us without looking for more suppliers or service agencies. This service model emphasizes efficiency, convenience, and user experience.