PCB Manufacturing Service

What is PCB Manufacturing Service

How can we help you?

Team Services

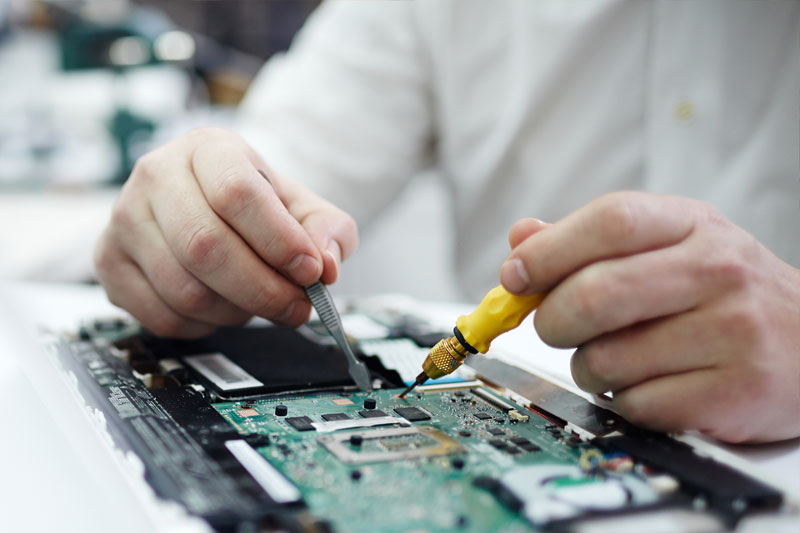

From the beginning, our experienced and qualified engineers and sales staff will work closely with you.

Service Programs

We will provide customized after-sales service solutions to meet different needs.

tracking service

After-sales service is not a one-time service, we provide continuous tracking service.

What is PCB Manufacturing Service

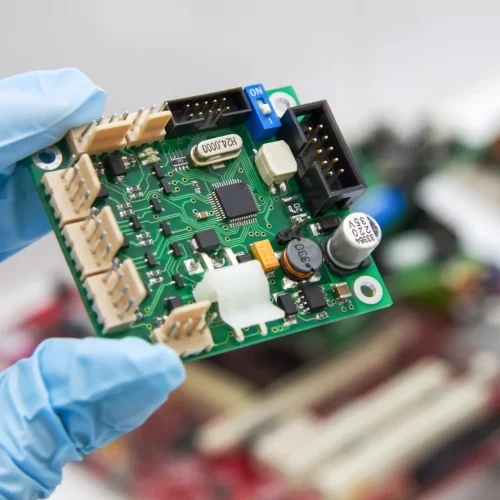

We focus on providing high-precision and high-reliability printed circuit boara manufacturing solutions. Our services cover everything from sample production to final large-scale batch production, adapting to the needs of various industries. We use the latest manufacturing equipment and technology. including multi-layer board manufacturing high-density interconnect (HDl) technology, and the production of flexible and rigid-flex boards.

Service process

01.Submit your Gerber data to our email.

provide your Gerber data through our channels

02.Evaluate your data

our team of engineers will carefully check your design or specifications and provide suggestions on how to improve your design

03.Production

using the final Gerber data, we ensure that the board accurately meets your specifications

04.Delivery cycle

we will determine the specific delivery date based on the design difficulty of each circuit board, and provide samples for your confirmation before mass production to ensure that you can personally verify the product results

05.Trial order

you can first order a small batch of PCB samples for testing Trial order can make you rest assured that the large batch of PCB boards you subsequently order will meet your standards.

06.Cooperation contract

signing a contract ensures that you confirm the structure and quantity of the PCB board before we start producing your order

07.Mass production

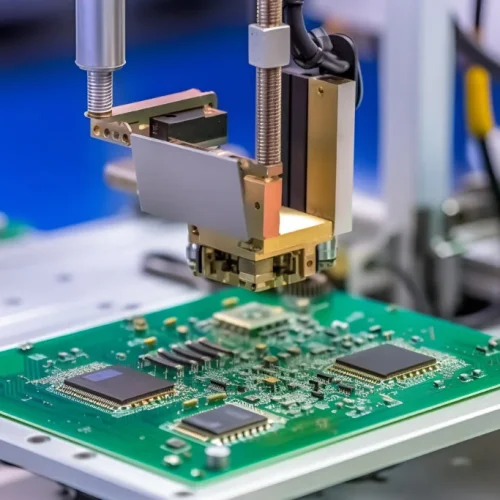

after signing the contract, we will use advanced manufacturing equipment to produce your PCB order within the expected period

08.Logistics distribution

all completed PCBs are assembled in customized packaging and arranged in cargo containers to ensure that they arrive safely and on time

Trusted PCB Manufacturing Services by Lingkey

When it comes to PCB manufacturing services, Lingkey is a trusted partner for high-quality and dependable solutions. Our team of experts is dedicated to providing you with exceptional PCB board service, whether you're developing advanced electronics or building efficient energy systems. We understand how critical it is for your project to succeed, which is why we ensure every PCB we manufacture meets the highest standards.

Why Choose Lingkey?

At Lingkey, the customer comes first.

01

02

03

04

The Importance of PCB Manufacturing

PCBs are the backbone of modern electronics. From electric vehicles to renewable energy systems, PCBs make it all possible by ensuring seamless communication between components. PCB manufacturing services play a crucial role in advancing new energy technologies by creating efficient and compact boards for electric vehicles, solar energy solutions, and other innovative applications. With a well-manufactured PCB, you can achieve higher performance, reliability, and energy efficiency in your products.

Our PCB Manufacturing Services

Lingkey is equipped to handle all aspects of PCB manufacturing services, from designing the layout to delivering finished boards. We have advanced facilities that support multi-layer PCB production. With our experienced team and cutting-edge machinery, we provide complex and high-precision PCB board service to meet a wide range of customer requirements. Whether it’s single-layer boards or highly intricate multi-layer solutions, Lingkey has the expertise to make it happen.

Fields of Application

Our PCBs are used in various industries

Automotive

Our PCBs are used in electric vehicles for power management and communication, helping make cars safer and more energy-efficient.

Medical Devices

Precision is key in medical equipment, and our PCBs ensure reliability in critical diagnostic tools and patient monitoring systems.

Consumer Electronics

From smartphones to smart appliances, our PCB board service supports high-quality consumer electronics with dependable connectivity.

Industrial Automation

We provide PCB manufacturing services for machinery that enhances factory efficiency, offering stability in high-pressure environments.

Renewable Energy

Our PCBs are utilized in solar inverters and wind energy systems, contributing to the clean energy revolution.

Meeting International Standards

At Lingkey, we are committed to quality and compliance. Our PCB manufacturing services meet international standards, ensuring that every board produced is of the highest quality. We adhere to ISO 9001, IPC standards, and other global certifications, guaranteeing that your products are ready for any market. Choose Lingkey for a reliable and comprehensive PCB board service that elevates your projects to the next level. We are here to provide the best PCB manufacturing services that meet your requirements and exceed your expectations.

Process Flow

01

Pre-manufacturing inspection

CAM inspection is a key link before PCB manufacturing. We will conduct a comprehensive analysis through professional software to check the design files to ensure that all layers, dimensions, apertures, etc. meet production requirements. This will optimize production efficiency, help prevent errors in production, reduce rework and scrap, and ensure that the final product can meet technical and functional requirements.

02

Raw material preparation

First, we will select a suitable substrate, usually glass fiber-reinforced epoxy resin (FR-4). We also provide a variety of PCB boards, such as CEM-1, EM1, CEM3, Fr1, FR-2, Fr4, aluminum-based PCB, metal core PCB, flexible PCB and rigid-flex PCB, and high-frequency PCB (PTFE). The choice of material depends on the application requirements of the final product, such as temperature stability, electrical insulation performance, and mechanical strength.

Cutting substrate: The substrate material is cut into appropriate sizes according to the size and design requirements of the PCB. We use professional equipment for cutting to ensure precise and clean edges.

03

Inner layer circuit

Inner layer pattern production is a key step in producing multi-layer PCBs. It accurately transfers the circuit pattern to the copper-clad substrate through coating photosensitive materials, photolithography exposure, development, and etching processes to ensure the functionality and reliability of the circuit.

04

Lamination (applicable to multi-layer PCB boards)

It is the most critical step in manufacturing multi-layer boards. In this step, all the individually made inner and outer layers, together with prepreg (an insulating material containing resin), are pressed and merged under high temperature and high pressure. This process ensures a strong bond between different layers and forms a solid multi-layer board, thereby ensuring the mechanical strength and electrical stability of the PCB.

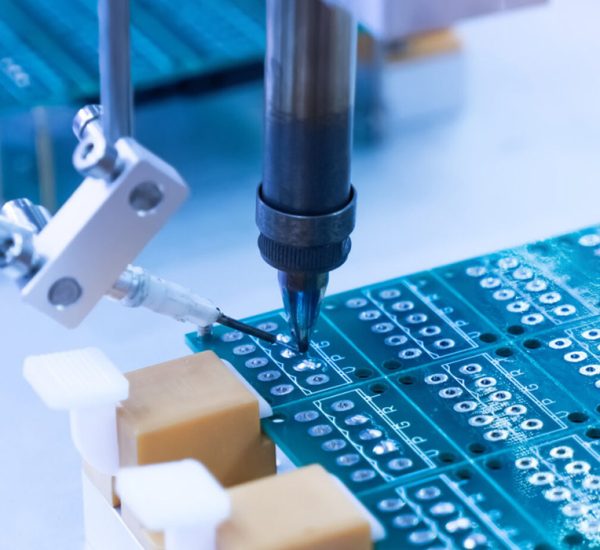

05

Drilling

Drilling is a key step in PCBs, mainly used to make holes and mounting holes on circuit boards. We will use high-precision CNC drilling machines to accurately control the location, size, and depth of the drilling according to the design files.

06

Copper deposition

The main purpose is to form a thin copper layer on the hole wall after drilling so that the subsequent electroplating process can deposit thick copper more evenly. Next, the copper layer adhesion of the hole wall is enhanced by micro-etching, and then the PCB is immersed in an activator and catalyst to prepare for the chemical deposition of copper. In the autocatalytic copper deposition stage, copper ions are automatically deposited on the activated hole wall to form a continuous copper layer without an external current.

07

Outer layer circuit

involves applying a photosensitive resist to the surface of the circuit board, and then accurately transferring the circuit pattern to the circuit board through photolithography exposure and development technology. Next, the unprotected copper layer is removed through an etching process to form the required circuit line.

08

Printing solder mask and silk screen

A solder mask is a layer of insulating material applied to the surface of the PCB. Its main function is to protect the copper line from environmental influences, prevent oxidation and short circuits, and also prevent solder misflow during the welding process. The solder mask is usually green, but it can also be red, blue, white, and other colors, depending on the manufacturer or design requirements.

Silk screen printing: mainly printing identification, such as component positioning marks, component numbers, logos, warning signs, etc.

09

Surface treatment, and cutting the whole circuit into unit pcb

Surface treatment: The main purpose is to protect the copper line from corrosion and oxidation while ensuring good welding performance. We can produce various types of surface treatments, such as HASL (suitable for cost-sensitive applications), ENIG (provides excellent welding performance and reliability, suitable for high-density components), ENEPIG (suitable for high-reliability requirements and aluminum wire bonding), and immersion silver (superior electrical performance, ideal for high-frequency applications).

Shearing and depaneling: Cut the circuit board into the size and shape you need, using methods such as mechanical shears, laser cutting, or water jet cutting. The board separation is carried out at the end of the process. It is mainly carried out by V-cutting, punching, or milling to divide the circuit board into unit pcs to ensure the independence and integrity of each board and the convenience of subsequent assembly.

10

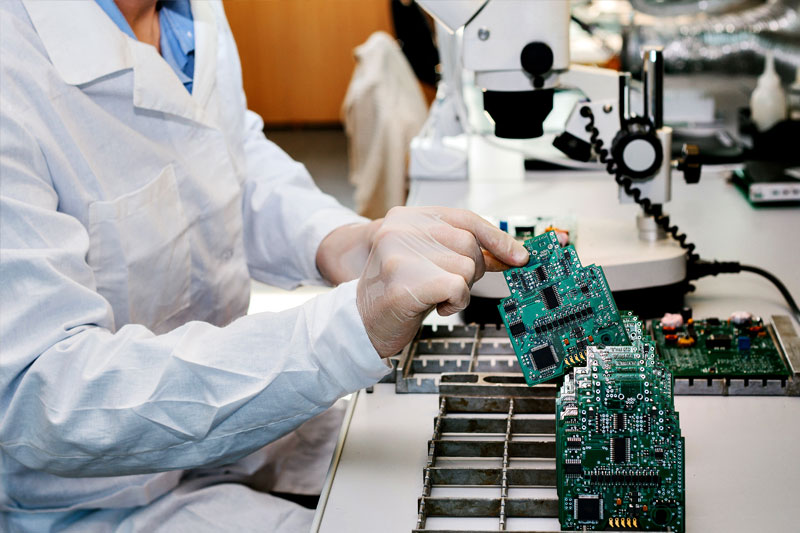

Electronic testing and FQC

Electronic testing: We will test each PCB. Usually, we will use a flying probe tester or a fixture tester to ensure that each circuit board meets the design specifications in function and there are no short circuits, open circuits, or other electrical faults.

FQC: It is mainly to check the overall appearance, use a caliper, micrometer, or automatic measuring equipment to check the size and hole position accuracy of the PCB to ensure that it meets the design documents.

11

Packaging and transportation

Before packaging, all PCBs must be thoroughly cleaned and dried. Vacuum packaging is carried out to ensure that the circuit board will not be damp for a certain period of time. All boards will be placed in cardboard boxes and protected with cushioning materials such as foam plastics, bubble film, or other fillers to ensure that they will not be damaged during transportation.

Transportation: We can transport the boards to you through various channels, such as DHL, USP, FedEx, TNT, etc. If you need sea or land transportation, it can also be supported.