Areas of application

01.

Discover

02.

Define

03.

Design

04.

Develop

05.

Deploy

06.

Deliver

Latest

In pharetra a felis odio eleifend hendrerit adipiscing id nulla sapien, ullamcorper ac, varius leo tellus sagittis consectetur egestas tortor, enim arcu blandit diam.

Silver Linings

Mi feugiat aliquet at elit urna consectetur et habitant erat elit nibh dictum purus

Baseless

Consequat ac dignissim sagittis, lobortis sit pulvinar nunc enim, dignissim

Curtain Fall

Diam urna tincidunt consectetur placerat vestibulum nam est cras

Once Bitten

Lacus orci integer eleifend eget phasellus hendrerit odio et mus

Technical Capabilities

Offering

Finished board thickness (thinnest – thickest)

Minimum Hole Diameter

Minimum line width/spacing

Maximum board size

Impedance control

Surface treatment process

Processing materials

1-48 layers

0.008″ ~ 0.24″

6mil (0.15mm)

3-4 mil (0.076-0.10mm)

Single and double layer 22″x 43″ (550 x 1100mm) Multilayer 22″x 25″ (550mm x 640mm)

± 10%

oxidation resistant OSP, tin spraying

FR4 (Sangyi, KB, International), high TG (TG150, TG170)

Aluminum PCB

Among various types of circuit boards, aluminum substrates are selected from many electronic devices due to their good heat dissipation and mechanical stability. They are ideal for high-power devices and LED applications. Next, let’s take a closer look at aluminum substrates.

What is a Aluminum PCB ? (aluminum pcb board /alu pcb)

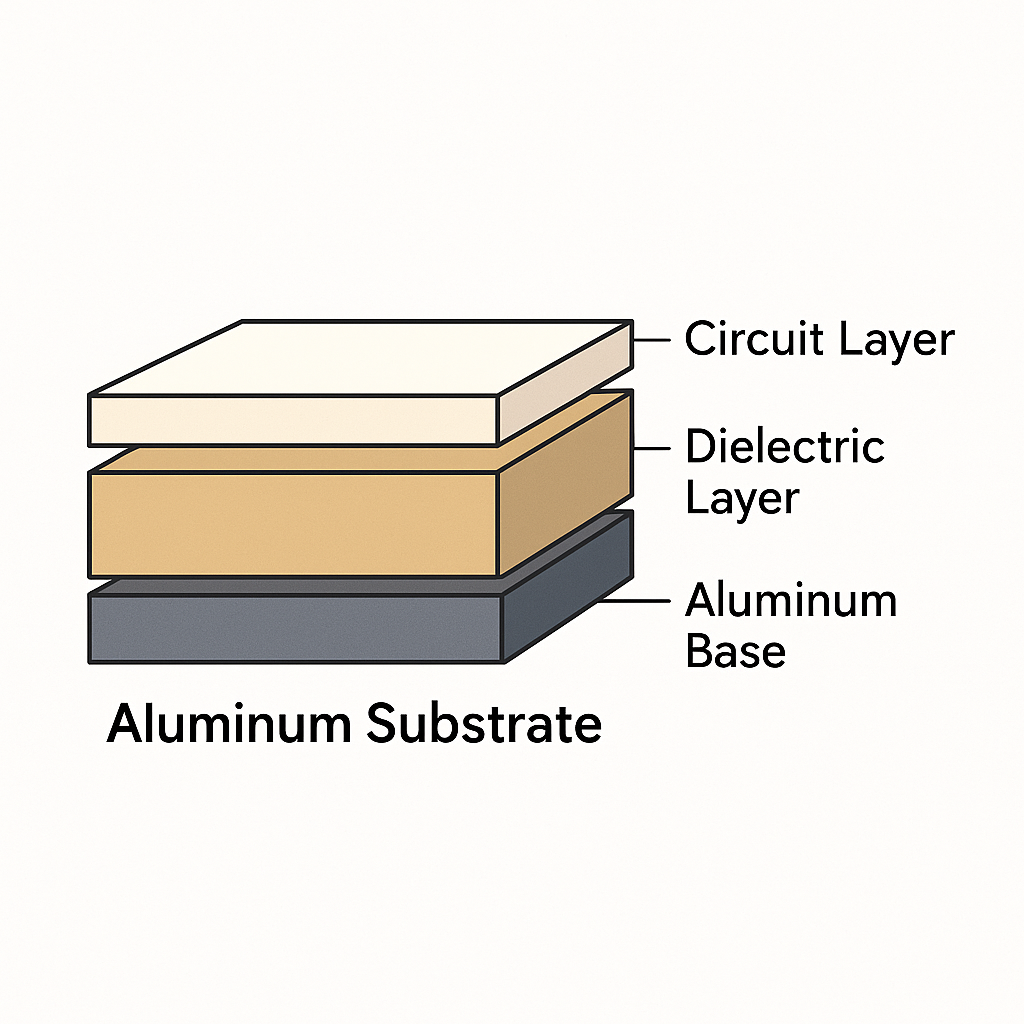

Aluminum substrate, also known as metal core substrate or aluminum core substrate, is a circuit board with aluminum as the base material.Unlike traditional circuit boards with FR4 as the base material, aluminum-based materials have good thermal conductivity and can conduct heat away from key components, thereby improving the stability and durability of circuit boards in high-power and high-temperature environments.

Construction & Technical Capabilities

Key Technical Specifications:

- Max Board Size: 600mm × 1200mm (supports large format and LED applications)

- Aluminum Thickness: 2mm–5mm+ (thickness of the aluminum customizable per application)

- Copper Thickness: 1–4 oz (high finished copper weight for advanced pcb)

- Layer Count: One-layer aluminum pcb, two-layer aluminum pcb, and multi-layer/hybrid aluminum core options

- Thermal Conductivity:2–8 W/m·K (higher available by request)

- Minimum Trace/Space: 150μm / 150μm

- Compliance: RoHS, UL, ISO9001, IPC-6012 or as required for your market

- Component Compatibility: SMDs, high-current devices, power LEDs, connectors, and both rigid pcb and flexible aluminum solutions

Layer & Material Structure:

Layer | Details |

Aluminum Base/Core | 2.0mm–5.0mm+ aluminum base, forming the core layer and providing excellent mechanical strength |

Dielectric Layer | High-performance dielectric with excellent thermal conductivity, customizable insulation thickness |

Copper Layer/Foil | 1–4 oz copper foil or laminate; supports demanding pcb design and high current routing |

Solder Mask | Various color options suitable for high-power LED applications and pcb assembly |

Surface Finish | ENIG, HASL, OSP, Immersion Silver—optimized for aluminum circuit boards and connector reliability |

advantages of Aluminum PCB

Compared with traditional FR4 PCB, aluminum base PCB has more efficient heat dissipation and better thermal conductivity.

Optimized dielectric layer, advanced aluminum materials, and copper foil layout for maximum thermal conductivity and low thermal resistance.

Rigid pcb construction with an aluminum base layer increases stability, reduces vibration, and protects core pcbs in harsh environments.

Aluminum boards and core technology resist warpage, support high current loads, and offer good thermal insulation for the long term.

As your preferred aluminum PCB manufacturer, each heavy duty aluminum PCB or aluminum PCB prototype reaches global standards (IPC, UL, ISO) to ensure quality.

Types of Aluminum PCBs We Offer

- Single-sided Aluminum PCB: Basic, cost-effective for bulk LED and consumer applications.

- Two-layer Aluminum PCB: Enhanced routing and performance, common in industrial and power electronics.

- Multi-layer/Hybrid Aluminum PCB: For complex energy management, battery arrays, and advanced circuit board technology.

- Flexible Aluminum PCB: Lightweight, high-quality aluminum for wearable or conformally mounted electronics.

- Custom Metal Core PCBs: Pre-engineered for the exact heat, mechanical, and electrical challenges of your projects.

Why choose Lingkey to cooperate

We operate a dedicated, independent factory with over 15 years of experience in aluminum PCB manufacturing and producing high-quality aluminum circuit boards. With fast production times and no minimum order quantity requirements, we can handle orders of any size. Equipped with flying probe testing, AOI, X-ray, and functional testing systems, all aluminum PCBs produced in our facility undergo rigorous testing for thermal conductivity, mechanical strength, and efficient heat dissipation to ensure comprehensive quality control. We are ISO 14001, UL, and ISO 9001 certified, meeting the stringent quality standards required for medical, automotive, and industrial control applications.