Flexible pcb

This comprehensive guide will lead you through the essential foundations and advanced knowledge you need to excel with flex pcb board solutions. application insights.

What is a Flexible PCB? (Flex PCB / Flex Circuits)

A flexible PCB—also called a flexible printed circuit, flex circuit, or fpc pcb—is a sophisticated circuit board made from electrically conductive materials on a flexible polymer base, typically polyimide (PI) or PET. Unlike rigid PCBs, a flexible pcb board can bend, twist, and conform to a product’s contours, making it a superior fit for today’s compact, high-density, and complex electronic designs.

Typical Flexible PCB Stackups

Build Type | Layers | Copper Thickness | Substrate | Vias | Coverlay | Stiffener |

Single-sided | 1 | 9–70 μm | PI/PET | No | Polyimide | Selective |

Double-sided | 2 | 9–70 μm both sides | PI | Yes (PTH) | Polyimide | Component |

Multi-layer | 3–12 | Custom | PI | Yes | Polyimide | Rigid area |

Rigid-flex | 2–20+ | Rigid + flex combo | FR4 + PI | Yes | Polyimide | Custom |

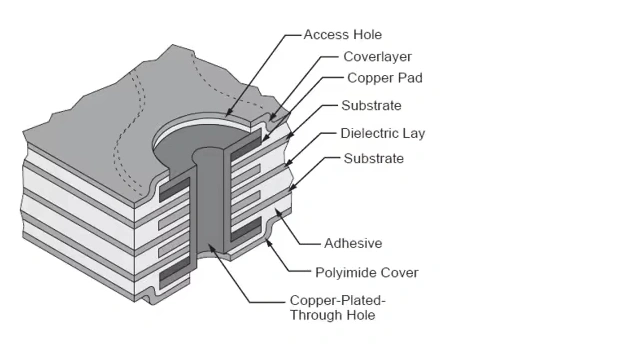

Flexible Printed Circuit Board Structure

Dielectric Substrate/Base Material

At the core of any flexible PCB is its substrate material. Polyimide (PI), with its excellent thermal stability, dielectric strength and flexibility is often chosen; PET may be chosen when less heat resistance but cost savings is desired. Your selection will directly affect reliability under both heat and flex loads.

Copper Conductors

Copper conductors are an effective path for current and signal transmission in the circuit. Highly dynamic flexible circuits are usually made of rolled annealed (RA) copper, while static or low-flex circuits use electrodeposited (ED) copper. Copper thickness can be specified from 9μm to 70μm (¼ ounce to 2 ounces or more) depending on the current load and mechanical bending needs.

Adhesive Materials

Special thermosetting or thermoplastic adhesives bond the copper foil to the base film. Typically, high temperature and chemical resistant epoxies or acrylics are used to ensure the integrity of the board through numerous flex cycles.

Protective Cover Film/Solder Mask:

This top layer protects the traces from environmental, chemical, and mechanical stresses. Polyimide cover films offer best-in-class toughness, while flexible solder masks offer an alternative for certain PCB assembly processes.

advantages of flexible PCBs

Eliminates bulky wiring harnesses and connectors, optimizing design and production in confined spaces

Withstands millions of flex cycles without trace cracking or delamination

Enables creative flex circuit design around corners, curves, or wearable shapes

Streamlines pcb and pcb assembly by integrating components directly onto the board

Resistant to vibration, thermal cycling, and moisture—ideal for automotive and aerospace systems

Flexible circuit application areas

- Consumer Electronics: Modern flex pcbs underlie smart watches, foldable phones, AR glasses, and advanced cameras. The ability to conform to rounded and wearable shapes is an undoubted advantage.

- Automotive Electronics: Flexible circuit boards are core to LED light strips, dashboard clusters, parking sensors, infotainment modules, and ADAS systems. In electric vehicles (EVs), aggressive space optimization and dynamic vibration resistance are must-haves.

- Medical Devices: FPCs are used for wearable health monitors, diagnostic skin patches, and next-gen implantables. Flexible, biocompatible substrates coupled with robust adhesives are ideal for such demanding, safety-critical markets.

- Telecommunications: Compact 5G antennas, radio modules, and high-density base station hardware depend on flexible and rigid-flex PCBs for tight RF control, improved reliability, and form factor reduction.

- Aerospace and Defense: Avionics, lightweight satellite modules, and radar subsystems benefit from the vibration resistance, temperature stability, and weight savings of multilayer flexible printed circuits and rigid-flex designs.

- Industrial Automation: Robotics, PLC controllers, and smart sensor interconnects all employ flexible circuitry for durability, reliability, and assembly efficiency under continuous motion.

Why choose Lingkey to cooperate

Flexible manufacturing, fast response

The independent, exclusive factory meets diverse flexible PCB production needs and can produce quickly. There is no minimum order quantity requirement, and orders of any quantity can be accommodated.

Comprehensive testing and quality assurance

The factory is equipped with testing systems such as flying probe testers, AOI, X-ray, and functional testing, ensuring full-process quality control.

Quality Assurance

We have obtained certifications such as ISO 14001, UL, and ISO 9001, fully meeting the strict quality standards required for medical, automotive, and industrial control applications.