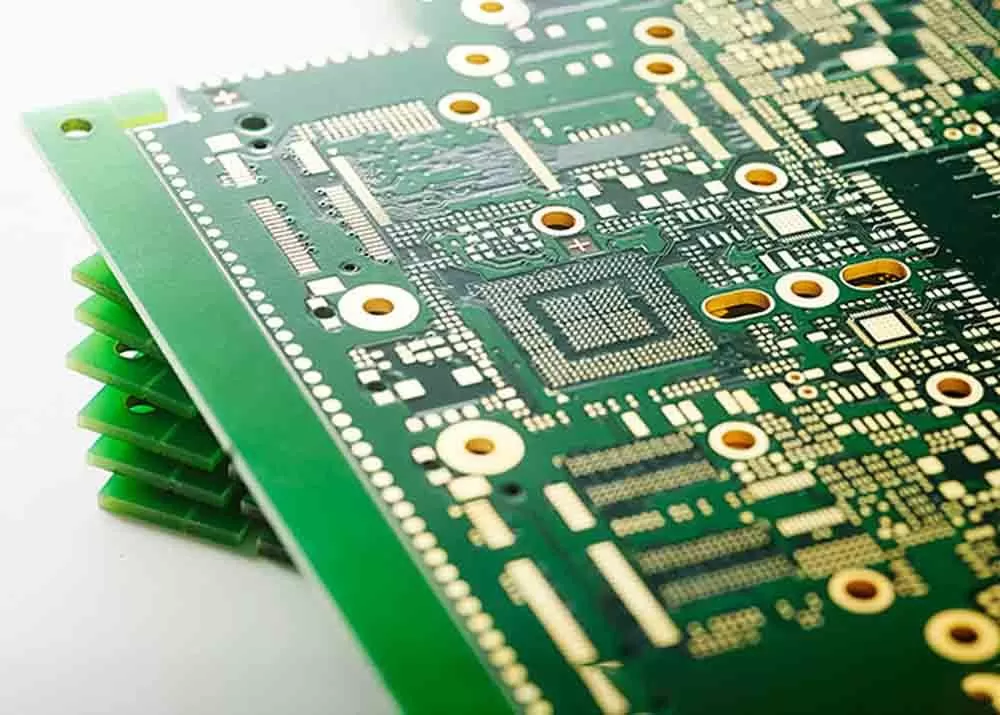

HDI PCB

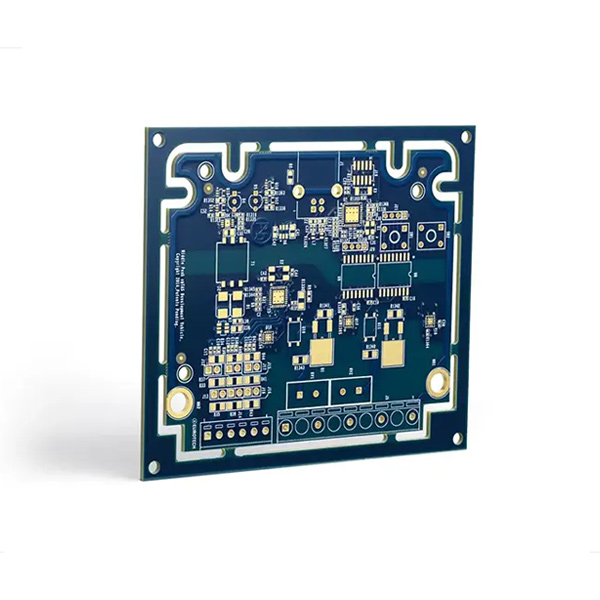

Basic information about this product from the company: High-density interconnect circuit board (HDI PCB) is an advanced type of printed circuit board (PCB) designed to accommodate higher-density circuit components.

What is HDI PCB?

Basic information about this product from the company: High-density interconnect circuit board (HDI PCB) is an advanced type of printed circuit board (PCB) designed to accommodate higher-density circuit components. HDI PCB utilizes fine lines and micro via technology, allowing more functions to be placed on the board while taking up less space. This technology is especially important for modern high-performance electronic devices, which require smaller, faster, and more powerful circuit boards.

High-Quality HDI Boards for Advanced Electronics

At Lingkey, we pride ourselves on being a leading HDI PCB supplier in the industry. We deliver premium, tailored HDI PCB solutions across a variety of industries. Our solutions encompass High-Density Interconnect (HDI) PCBs, renowned for their dense wiring per unit area. This makes them an ideal choice for both compact and high-performance electronic devices.

Microvias in HDI PCB

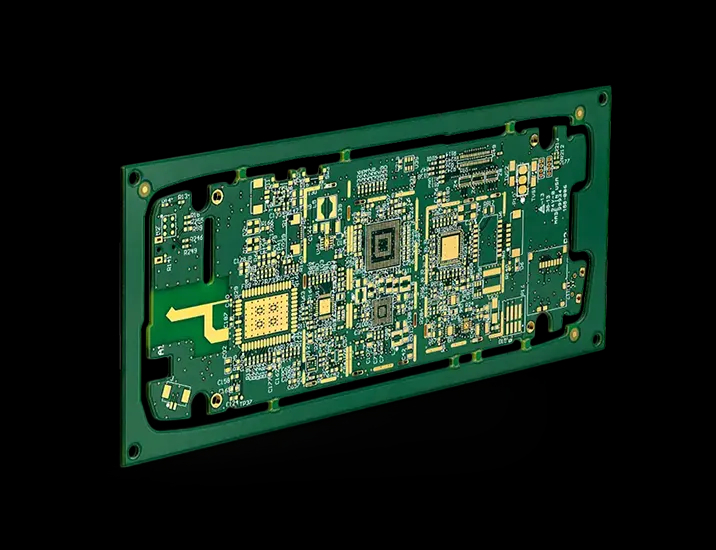

A key feature of our HDI PCBs is their high component density and the incorporation of microvias.These not only allow for a compact layout, but also allow the use of finer lines, smaller vias, and capture pads. Consequently, our HDI boards are a popular choice among top manufacturers who are looking to improve performance and while also reducing the size of their products.

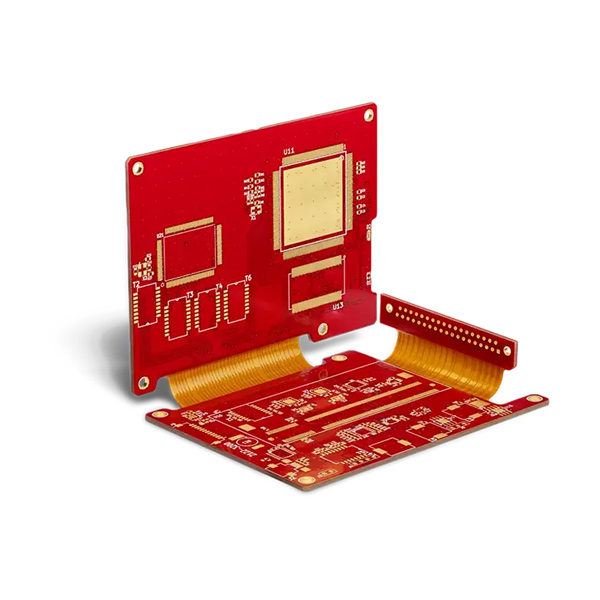

In HDI PCB design, we employ various types of vias to facilitate the required interconnections. These include:

01.

Stacked Vias

These vias are positioned directly atop one another across several layers of a PCB.These vias are laser-drilled and filled with conductive material to create a vertical stack to multiple layers. These are commonly used in HDI PCBs to create precise connections in a very compact area and are often used in devices like smartphones and tablets.

02.

Stacked Microvias

These are a specialized variant of stacked vias, utilizing microvias.These microvias are usually filled and plated to ensure solid connections. These are used to provide high-density interlayer connections, particularly in complex HDI PCB designs.

03.

Stacked Microvias

Staggered Vias: These vias are positioned on separate layers, not directly aligned one above the other. Instead of stacking, the vias are positioned in a staggered pattern which connects multiple layers indirectly. These are commonly used in high-frequency or high-density PCBs, such as those for RF or microwave applications.

Quality Control and Precision

At Lingkey, we take pride in our product quality and meticulous precision. Our state-of-the-art manufacturing facilities, coupled with stringent Quality Control measures, enable us to deliver high-quality HDI PCB solutions that meet international standards. We also use technologies like advanced laser drilling, high-precision copper plating, and state-of-the-art lamination processes to ensure that our HDI boards meet the required specifications. This focus on quality control is what allows us to craft HDI PCB solutions boasting superior electrical performance and enhanced mechanical stability for high-end electronic products.

Why Choose Lingkey HDI PCB Supplier?

As a trusted HDI PCB supplier, Lingkey serves the HDI board needs of industries such as automotive, medical, telecommunications, and consumer electronics. Each of these sectors demands compact, high-performance solutions, a standard our HDI boards consistently meet. So, whether you’re developing medical imaging equipment, advanced driver-assistance systems, or high-speed communication devices, Lingkey’s HDI PCBs offer the right solutions as per your specific needs.

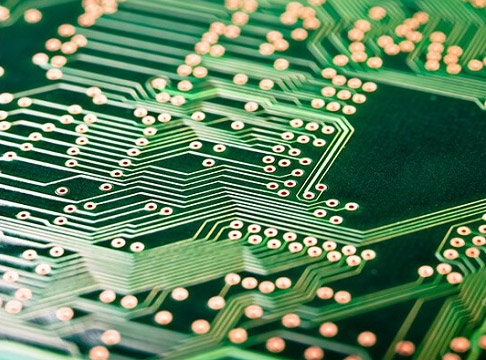

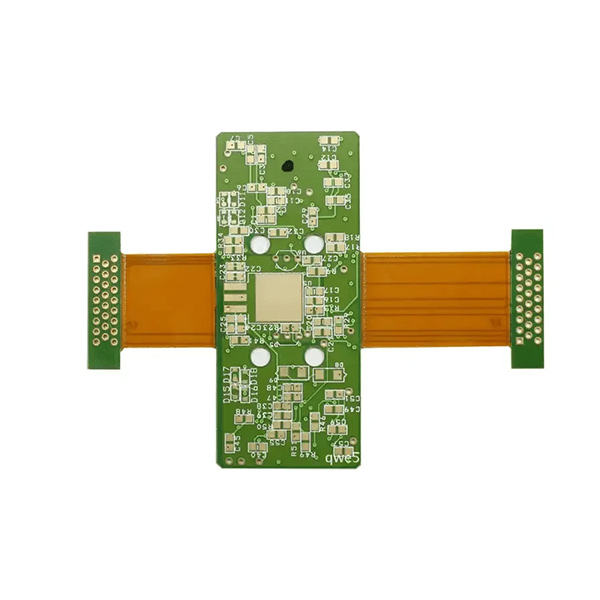

Characterization

HDI PCBs use microvias that are typically less than 0.006 inches (150 microns) in diameter. These microvias can be blind (connect only the outer layer to one or more inner layers), buried (connect only between inner layers), or through holes (through the entire board). The use of microvias greatly reduces the size and weight of the PCB while improving signal integrity. Fine Lines and Spacing: Allows for finer line widths and spacing, typically less than 100 microns. This makes more complex circuit designs possible, while more electronic components can be accommodated on the board. Stacking and Interconnection

HDI PCBs can adopt a multi-layer stacking structure, which makes the interconnection more complex and tight by using multiple layers of microvias and thin materials.

Due to shorter signal paths and optimized layouts, HDI PCBs perform better in high-frequency applications, reducing signal loss and crosstalk.

Shorter signal paths and the use of microvia technology help reduce signal delays and improve overall circuit

Latest

In pharetra a felis odio eleifend hendrerit adipiscing id nulla sapien, ullamcorper ac, varius leo tellus sagittis consectetur egestas tortor, enim arcu blandit diam.

Silver Linings

Mi feugiat aliquet at elit urna consectetur et habitant erat elit nibh dictum purus

Baseless

Consequat ac dignissim sagittis, lobortis sit pulvinar nunc enim, dignissim

Curtain Fall

Diam urna tincidunt consectetur placerat vestibulum nam est cras

Once Bitten

Lacus orci integer eleifend eget phasellus hendrerit odio et mus

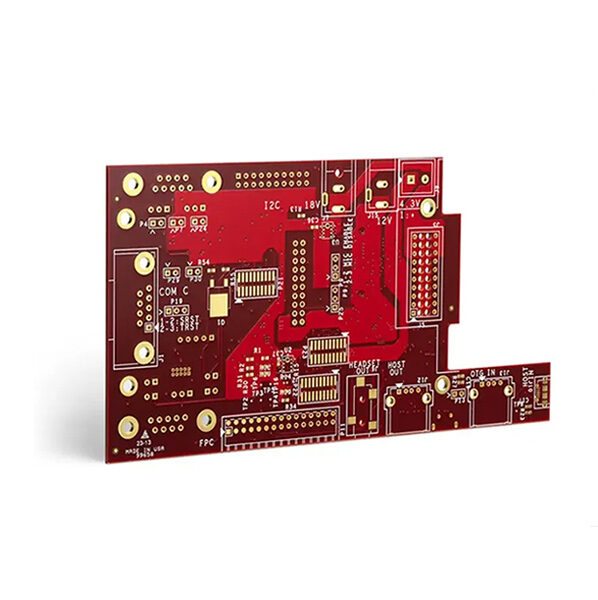

Technical Capabilities

Offering

Finished board thickness (thinnest – thickest)

Minimum Hole Diameter

Minimum line width/spacing

Maximum board size

Impedance control

Surface treatment process

Processing materials

1-48 layers

0.008″ ~ 0.24″

6mil (0.15mm)

3-4 mil (0.076-0.10mm)

Single and double layer 22″x 43″ (550 x 1100mm) Multilayer 22″x 25″ (550mm x 640mm)

± 10%

oxidation resistant OSP, tin spraying

FR4 (Sangyi, KB, International), high TG (TG150, TG170)