rigid flex pcb

A rigid-flex PCB (also known as rigid-flex PCB, rigid-flex printed circuit board, or rigid-flex circuit) is a type of bonded printed circuit board that combines the ruggedness of a rigid PCB with the versatility of a flexible circuit into a single, reliable assembly.

What is a Rigid-flex PCB?

Rigid-flex printed circuit board (rigid flex pcb) is a circuit board that combines the advantages of rigid circuit boards and flexible circuit boards. It not only has the excellent bendability of flexible circuit boards, but also has the tensile strength of rigid circuit boards. This makes them a popular choice for applications such as medical devices, military applications, aerospace, and smartphones. Its flexibility allows users to freely install it precisely into complex packaging geometries.

Rigid-Flex PCB Construction and Technical Capabilities

Core Structure and Materials:

Layer | Details |

Substrate | High-temp polyimide for flex layers; FR4 and high-TG laminate for rigid parts |

Copper Layer | 1–4 oz copper, supporting single to multiple layers of flexible circuit and power/ground planes |

Stackup | Hybrid layer stackup with flexible circuit substrates attached to one or more rigid sections |

Soldermask | Coverlay or LPI soldermask—selective for both rigid and flex pcb design needs |

Finish | ENIG, Immersion Silver, OSP, Gold Selective—ensuring quality manufacturing processes |

Key Technical Specifications:

- Max Board Size: Up to 500mm x 500mm (custom on inquiry)

- Layer Count: 2 to 14 layers; single or multiple layers of flexible circuit in complex stackups

- Minimum Trace/Space: Down to 75μm / 75μm

- Bend Radius: Flexible circuit supports bending radii from 0.8mm, supporting dynamic flex operations

- Impedance Control: Optimized signal integrity across interconnects with controlled impedance

- Certifications: RoHS, UL, IPC-6013, ISO9001

- Assembly: Supports SMT, BGA, and through-hole on rigid and flex zones

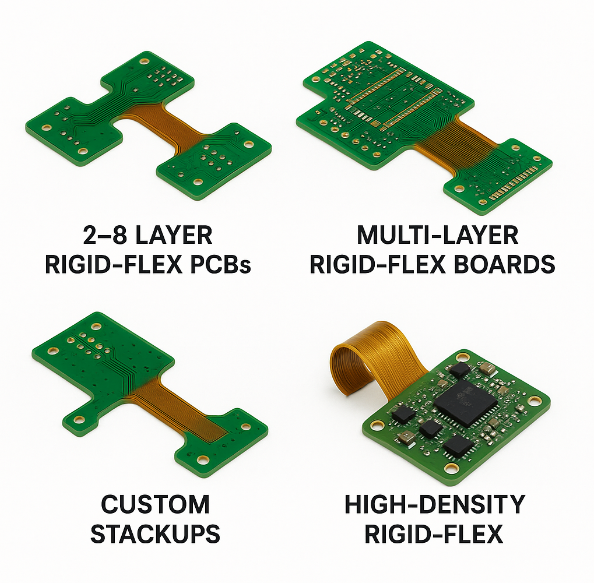

Types of Rigid Flex PCBs We Offer

2–8 Layer Rigid Flex PCBs

Balancing rigid and flexible regions for consumer and industrial products

Multi-layer Rigid-Flex Boards:

Up to 14 layers, supporting high I/O density and advanced flex and rigid-flex designs

Custom Stackups

Unique blend of flexible and rigid for 3D or foldable circuits

High-Density Rigid-Flex

For miniaturized wearables and medical sensors

Prototype to Production

From conceptual design phase to large-scale manufacturing and assembly

Advantages of Rigid-Flexible PCB

Our rigid-flex PCBs consist of interconnected rigid and flexible areas, maximizing layout freedom and mechanical stability.

By eliminating traditional cable and interboard connectors, rigid-flex boards support reduced assembly and higher reliability.

Supports the connection of multi-layer flex circuits and flex circuit substrates to one or more rigid sections for ultimate PCB design flexibility.

Withstand bending, shock, vibration, and complex mechanical stresses—improving overall system reliability in dynamic and mission-critical environments.

Expert design phase/process guidance for manufacture and assembly, ensuring manufacturability and lower production risk.

Ideal for space- and weight-sensitive applications, rigid-flex pcbs allow intricate 3D routes and support both high-speed and analog signals.

Applications of Rigid-Flex PCBs

- Aerospace & Defense: Satellite systems, avionics, missile electronics, and rugged communications equipment are all about high-reliability rigid-flex designs.

- Medical devices: Implantable sensors, hearing aids, surgical instruments—high demands on rigid-flex circuit manufacturability and flexibility.

- Consumer electronics: Foldable phones, cameras, wearables, and advanced gaming consoles, all of which require durable, thin circuit interconnects.

- Automotive: Airbag controllers, cameras, infotainment modules, and HUD systems require multi-plane assembly and durability in harsh environments.

- Industrial & Robotics: Robotic arms, motion sensors, controllers—combining flexible sections with rigid areas to enable dynamic, space-constrained settings.

- Telecommunications: Compact base stations, high-speed modules, and antenna systems—where the flexibility of flexible circuits and high-frequency signal transmission are critical.

Why choose Lingkey to cooperate

PCB manufacturing, fast response

Our rigid flex PCB manufacturing combines best-in-class materials with advanced fabrication and assembly processes to meet the challenges of both traditional rigid PCBs and new market needs for dynamic flex capability.

Comprehensive testing and quality assurance

The factory is equipped with testing systems such as flying probe testers, AOI, X-ray, and functional testing, ensuring full-process quality control.

Quality Assurance

We have obtained certifications such as ISO 14001, UL, and ISO 9001, fully meeting the strict quality standards required for medical, automotive, and industrial control applications.