Expert Prototype PCB Assembly Services for Businesses

Prototype PCB assembly is the process of creating small-batch circuit boards to test and validate electronic designs. Unlike mass production, this stage focuses on identifying and addressing potential design issues.

A prototype PCB board serves as the foundation for evaluating functionality, verifying performance, and making improvements before full-scale manufacturing begins. By simulating real-world conditions, these assemblies provide valuable insights into potential optimizations, saving time and reducing costs in the long run.

Lingkey

Prototype PCB Board Application Industry

Prototype PCB boards are essential across a wide range of industries.

●In consumer electronics, they aid in developing innovative gadgets and devices.

●The medical field uses them to test diagnostic tools and wearable technology.

●Automotive industries rely on prototypes to refine advanced driver-assistance systems (ADAS) and in-car electronics.

●In industrial automation, prototype PCBs support the creation of control systems and robotics.

●Telecommunications also benefit from using them to validate high-speed networking hardware.

Common Features of Prototype PCB Boards

Lingkey has a great advantage in the design and manufacture of prototype PCB boards, and has good control over its common features:

Focused Design Validation

Prototype PCBs are produced in small quantities, allowing engineers to dedicate resources to refining and validating designs effectively.

Flexible Configurations

Customization options ensure each board is uniquely suited to test specific functionalities, enabling comprehensive analysis of critical components.

Accelerated Development Cycles

Rapid manufacturing supports iterative testing, helping developers address potential issues and improve designs without unnecessary delays.

Precision Craftsmanship

These boards replicate the intended design with a high level of accuracy, ensuring consistent results during testing and eventual scaling for mass production.

Features of Prototype PCB Assembly

High flexibility

Prototype PCB assembly usually does not require a strict production line setup, allowing for quick changes and adaptations to designs.

Cost and time efficiency

Although the cost per piece may be higher, the rapid iteration of prototypes can greatly shorten the product development cycle and reduce overall project costs.

Low volume production

Prototypes are usually produced in small batches, sufficient for effective testing without large-scale investment.

Lingkey’s Process and Capabilities

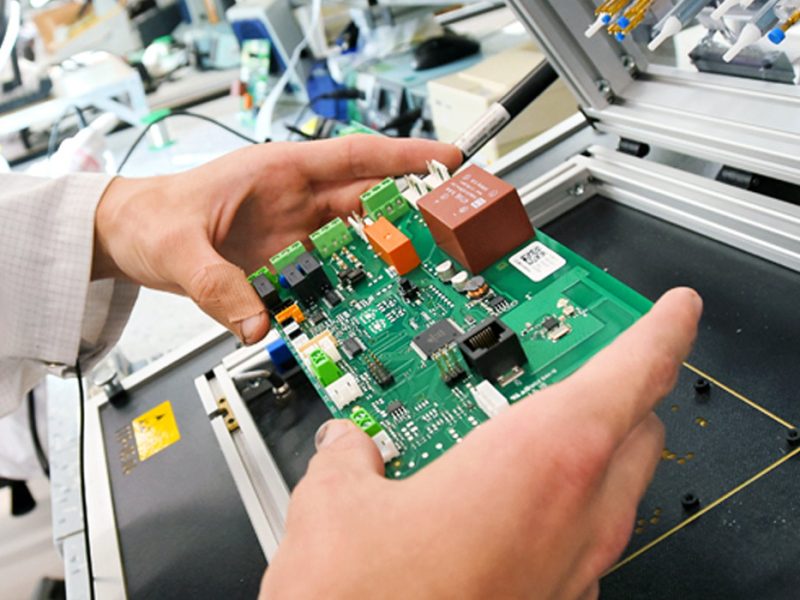

At Lingkey prototype PCB board manufacturer, we combine advanced technology with expert craftsmanship to deliver top-tier prototype PCB assembly services. Our process includes:

Design Review

Our engineers collaborate with clients to evaluate designs and recommend improvements.

Precision Assembly

Advanced equipment ensures accurate placement of components on prototype PCB boards.

Testing and Debugging

Rigorous testing identifies potential issues, ensuring the highest level of reliability.

Rapid Prototyping

Quick turnaround times meet tight deadlines without compromising quality.

Why Choose Lingkey for Prototype PCB Assembly?

Lingkey prototype PCB board manufacturer offers unique advantages that set us apart in the industry:

- Expert Engineers:Our team has extensive experience in prototype PCB assembly, ensuring flawless results.

- Advanced Technology:State-of-the-art equipment supports precision and efficiency.

- Custom Solutions:We tailor our processes to meet the unique needs of every project.

- Rigorous Testing:Comprehensive testing guarantees reliable and functional prototypes.

- Fast Turnaround:Our streamlined processes minimize delays, helping clients stay on schedule.

Common Questions

Prototype PCB assembly focuses on small batches for testing and refinement, while mass production involves large quantities of finalized designs.

We use advanced machinery, rigorous testing, and a thorough design review process to deliver precise and reliable prototypes.

Yes, our expertise and technology as a prototype PCB board manufacturer enables us to manage intricate and innovative designs with ease.

Steps of Prototype PCB Assembly

01

Design and Output PCB Layout

First, use electronic design automation (EDA) software to design the PCB layout and generate the data files required for manufacturing, usually Gerber files and drill files.

02

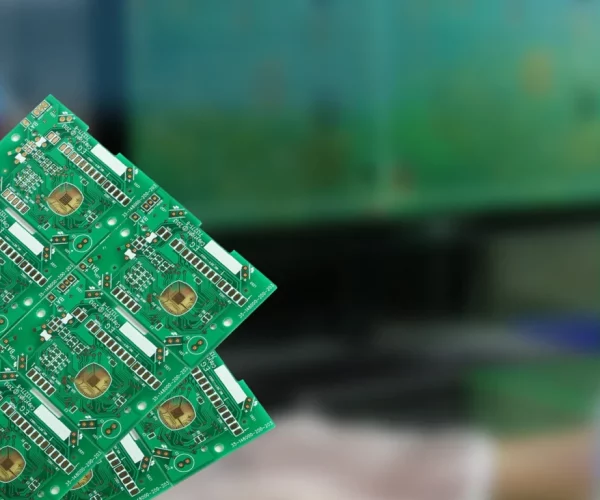

PCB Manufacturing

According to the design files, a blank PCB is manufactured by methods such as chemical etching or laser processing.

03

Component Procurement

Obtain all the electronic components required for prototyping. In the prototype stage, the selection of components can be more flexible to speed up development.

04

Printing Solder Paste

If surface mount technology (SMT) is used, solder paste needs to be printed on the corresponding pads of the PCB.

05

Component Placement

Electronic components are placed on the PCB using manual or automatic placement machines. For prototypes, manual placement is more common, especially when the number of components is small.

06

Soldering

Fixing of components is completed by reflow soldering or manual soldering. For through-hole components, wave soldering or manual soldering may be required.

07

Inspection and Testing

After assembly is completed, visual inspection, X-ray inspection, and functional testing are performed to ensure that all components are properly installed and the circuit functions properly.

08

Iteration

Iterative modifications to the design are made based on the test results and problems found, which may require