Meaning of SMT Stencil Assembly

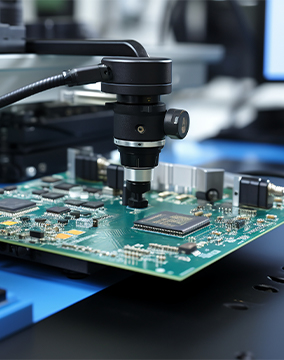

In Surface Mount Technology (SMT), an SMT stencil is a critical tool for precise solder paste application. It serves as a thin, laser-cut or chemically etched sheet, used to transfer solder paste onto the pads of a printed circuit board (PCB). The stencil ensures accurate alignment, enabling efficient and reliable solder joint formation during reflow soldering. This process significantly influences the quality and consistency of electronic assembly.

SMT Stencil Product Type

SMT stencils come in various forms to meet diverse production requirements. Common types include:

- Framed Stencils: Equipped with a frame for rigidity and precision.

- Frameless Stencils: Lightweight and cost-effective for short production runs.

- Electroformed Stencils: Ideal for fine-pitch components due to their smooth aperture walls.

- Nano-coated Stencils: Designed for enhanced solder paste release and reduced cleaning needs.

These stencils are manufactured using PCB stencil materials like stainless steel and nickel, known for their durability and precision.

Use and maintenance of SMT stencils

Use

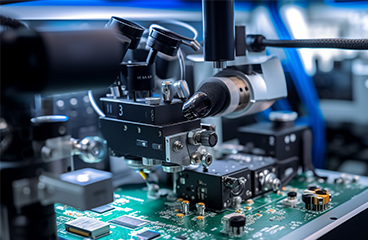

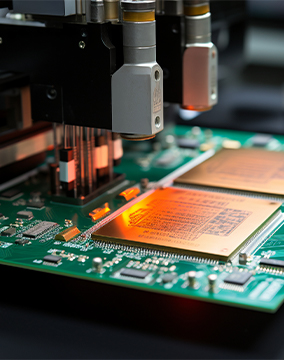

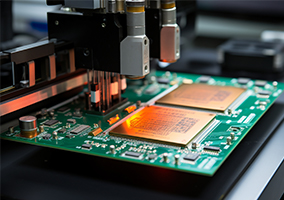

On the SMT production line, the stencil is first fixed on the printer. Subsequently, the solder paste is pressed into the openings of the stencil by the pressure of the scraper and transferred to the pads of the PCB through the mesh.

The consistency and accuracy of solder paste printing are critical to the subsequent reflow process and the quality of the final product.

Cleaning and maintenance

The cleaning of the stencil is very important to maintain the printing quality. After use, the stencil needs to be cleaned regularly to remove residual solder paste and prevent clogging.

Cleaning can be performed using special cleaning agents and ultrasonic cleaning machines.

Storage

Unused stencils should be properly stored in a dry and clean environment to avoid

Lingkey's Technical Capabilities

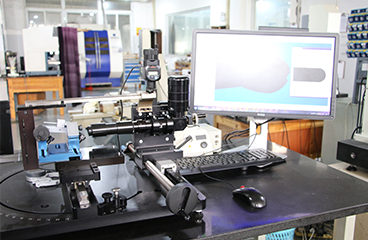

Lingkey specializes in producing high-quality SMT stencils using advanced manufacturing technologies. The company’s capabilities include:

- Laser Cutting: Ensuring precise aperture dimensions for consistent solder paste application.

- Electroforming: Producing smooth, burr-free stencil openings for fine-pitch PCBs.

- Nano-coating: Extending stencil life and improving solder paste release efficiency.

- Customization: Designing stencils tailored to specific PCB designs and customer requirements.

Lingkey’s state-of-the-art equipment and skilled technicians guarantee superior results in stencil production.

Lingkey's Advantages

Lingkey offers several distinct advantages:

- High Precision: Advanced laser-cutting technology ensures superior accuracy.

- Custom Solutions: Flexible designs to meet unique PCB stencil material

- Durable Materials: Use of high-quality stainless steel, nickel, and PCBstencil material for longevity.

- Fast Turnaround: Quick production and delivery timelines.

- Comprehensive Support: Expert guidance on stencil design and application.

Industries supported by Lingkey's SMT Stencils

On the SMT production line, stencils ensure consistency and accuracy, enhancing final product quality. By leveraging high-quality PCB stencil materials, Lingkey provides solutions tailored to the demands of diverse industries.

Maintenance and Storage Tips: Regular cleaning and proper storage in a clean, dry environment help extend stencil lifespan and ensure optimal performance.

Consumer Electronics

Smartphones, wearables, and household devices.

Automotive

Electronic control units and infotainment systems.

Medical Devices

Diagnostic equipment and patient monitoring systems.

Industrial Applications

Automation and control systems.

Aerospace

High-reliability PCBs for navigation and communication.

Common SMT Stencil Questions

Stainless steel is commonly preferred for its durability.

Regular cleaning after every production cycle is recommended to maintain quality.

Yes, with proper cleaning and storage.

Usage frequency, cleaning practices, and solder paste type.